In the rapidly evolving landscape of modern agriculture, the integration of artificial intelligence (AI) and automation is becoming increasingly vital. A recent study published in the journal *Foods* (translated from Chinese) introduces a novel method that could revolutionize the way we sort and grade tomatoes, one of the world’s most widely consumed fruits. The research, led by Ziheng Liang from the College of Mechanical and Electronic Engineering at Nanjing Forestry University, presents YOLO-RGDD, a cutting-edge model designed to detect surface defects in tomatoes with remarkable accuracy and efficiency.

Traditional methods of tomato sorting rely heavily on manual labor, a process that is not only time-consuming but also prone to human error. “The manual screening process is inefficient and involves high labor intensity,” explains Liang. “Our goal was to develop a system that could automate this process, ensuring quality control while reducing the burden on workers.”

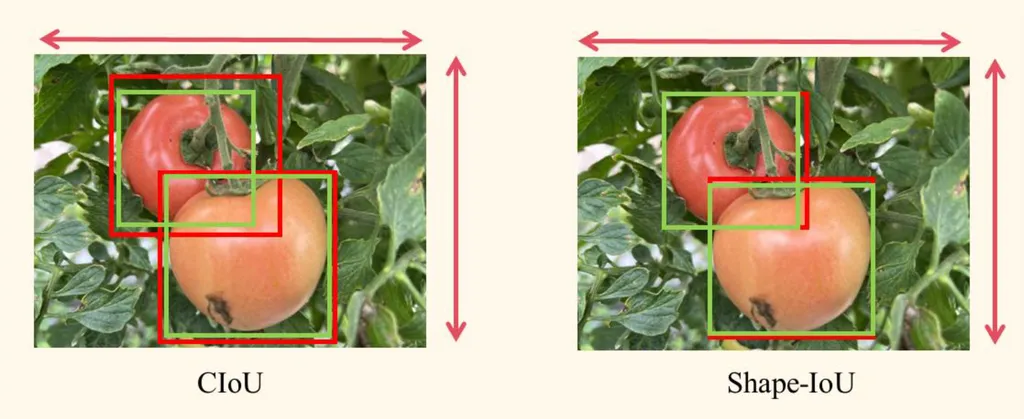

The YOLO-RGDD model is an advanced version of the YOLOv12s algorithm, specifically tailored for detecting five types of tomato surface defects: scars, gaps, white spots, spoilage, and dents. The researchers made several key improvements to the original model. They replaced the original C3k2 module and A2C2f module with a new feature extraction module called RFEM, enhancing the model’s ability to detect small defects without increasing computational complexity. Additionally, they developed a new structure called Dysample–Slim-Neck to further reduce computational complexity and improve defect detection. Finally, they employed dynamic convolution in the detection head to reduce the model’s parameter count.

The results of the study are impressive. The YOLO-RGDD model achieved an average precision of 88.5%, a recall rate of 85.7%, and an F1-score of 87.0%, outperforming other advanced object recognition detection algorithms. Moreover, the computational complexity of YOLO-RGDD is 16.1 GFLOPs, which is 24.8% lower than that of the original YOLOv12s model, making it more suitable for deployment in automated agricultural production.

The implications of this research are significant. As the demand for high-quality agricultural products continues to grow, the need for efficient and accurate sorting methods becomes ever more critical. The YOLO-RGDD model offers a promising solution, one that could not only improve the economic value of tomato products but also enhance food safety and quality control.

Looking ahead, the success of YOLO-RGDD could pave the way for similar AI-driven solutions in other areas of agriculture. “This research is just the beginning,” says Liang. “We believe that AI and automation will play an increasingly important role in modern agriculture, helping to address some of the sector’s most pressing challenges.”

As the world grapples with issues such as food security and sustainability, innovations like YOLO-RGDD offer a glimmer of hope. By harnessing the power of AI, we can work towards a future where agriculture is not only more efficient but also more resilient and sustainable. The research published in *Foods* is a testament to the transformative potential of technology in agriculture, and it will be exciting to see how this field continues to evolve in the years to come.