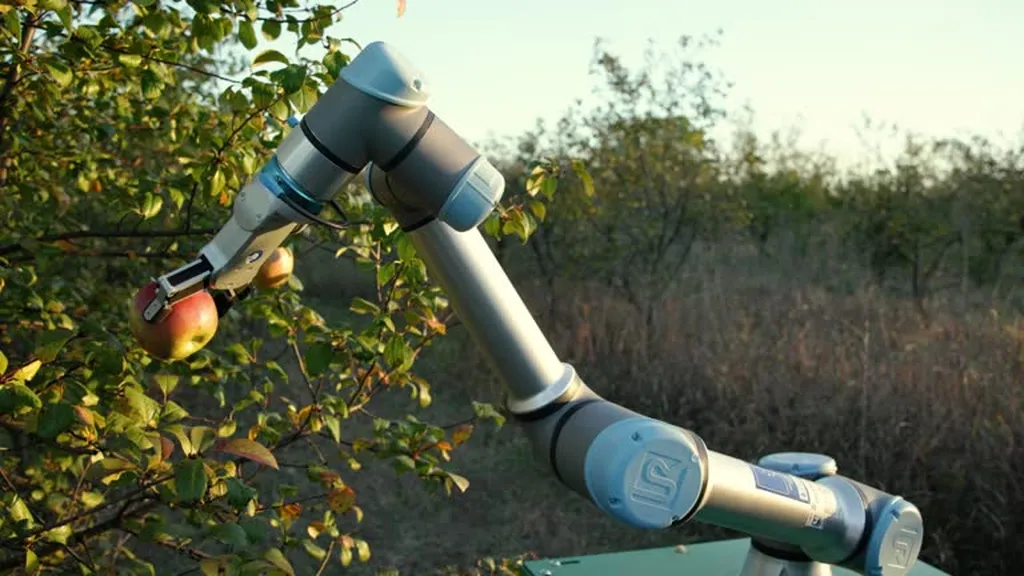

In the heart of China’s ancient capital, Xi’an, a modern revolution is brewing in the fields of horticulture. Bin Yan, a researcher at the College of Automation and Information Engineering, Xi’an University of Technology, is leading a charge to transform the way we harvest apples. His team has developed a dual-arm apple-picking robot, a significant leap from the single-arm models that have dominated the market. This innovation, detailed in a recent study published in the open-access journal Horticulturae (which translates to “Horticulture”), could reshape the future of smart horticulture and precision agriculture.

The problem with single-arm robots, Yan explains, is that they’re like “a one-handed juggler.” They can do the job, but they’re not as efficient as they could be. “Most existing apple-picking robots operate with a single arm,” Yan says, “and while they function, the overall efficiency of the machine needs to be further improved.” Enter Yan’s dual-arm robot, a prototype that promises to boost efficiency and productivity in apple orchards.

The robot’s design is a marvel of modern engineering. Based on the configuration and motion mode of the AUBO-i5 robotic arm, Yan and his team determined the optimal overlapping dual-arm layout of the workspace. This layout is the secret sauce behind the robot’s impressive performance. In simulation experiments, the robot achieved a maximum parallel operation proportion of up to 83%, with the lowest being 50.6%. This means that both arms were working simultaneously for most of the time, significantly speeding up the picking process.

But the innovation doesn’t stop at the robot’s design. Yan and his team also developed a dual-arm picking operation zoning planning method and a fruit-picking sequence planning method based on dual robotic arm operation. These methods ensure that the robot’s arms don’t get in each other’s way, further improving efficiency. “There was no conflict between the left and right arms during the motion of the dual robotic arms,” Yan notes, highlighting the seamless coordination between the robot’s limbs.

The results of the study are promising. In real-world tests at an apple experimental station, the robot achieved a dual-arm parallel operation proportion ranging from 50.7% to 72.4%. The total length of the dual-arm operation path varied from 6511 mm to 8604 mm. These figures may seem like mere numbers, but they represent a significant leap forward in the field of smart horticulture.

So, what does this mean for the future of apple picking and precision agriculture? Yan’s research could pave the way for more efficient, more productive apple orchards. With robots like Yan’s dual-arm model, farmers could harvest their crops faster and with less labor, reducing costs and increasing yields. This could have a ripple effect throughout the agricultural industry, driving innovation and growth in the sector.

Moreover, this research could inspire similar developments in other areas of horticulture and precision agriculture. As Yan puts it, “This is just the beginning. There’s so much more we can do with dual-arm robots in agriculture.” With each passing day, the fields of smart horticulture and precision agriculture are evolving, and Yan’s research is a testament to that. As published in Horticulturae, this study is a beacon of innovation, guiding the way towards a more efficient, more productive future for agriculture.