In the quest for safer and more efficient industrial practices, a team of researchers led by Yiyang Xu from the School of Aerospace Science and Technology at Xidian University in Xi’an, China, has made significant strides in the development of ammonia gas sensors. Their work, published in the journal *Micromachines* (which translates to *Micromachines* in English), focuses on the use of MXene, a class of two-dimensional materials known for their unique properties, to detect ammonia—a toxic and corrosive gas prevalent in industrial emissions, agricultural activities, and even as a disease biomarker.

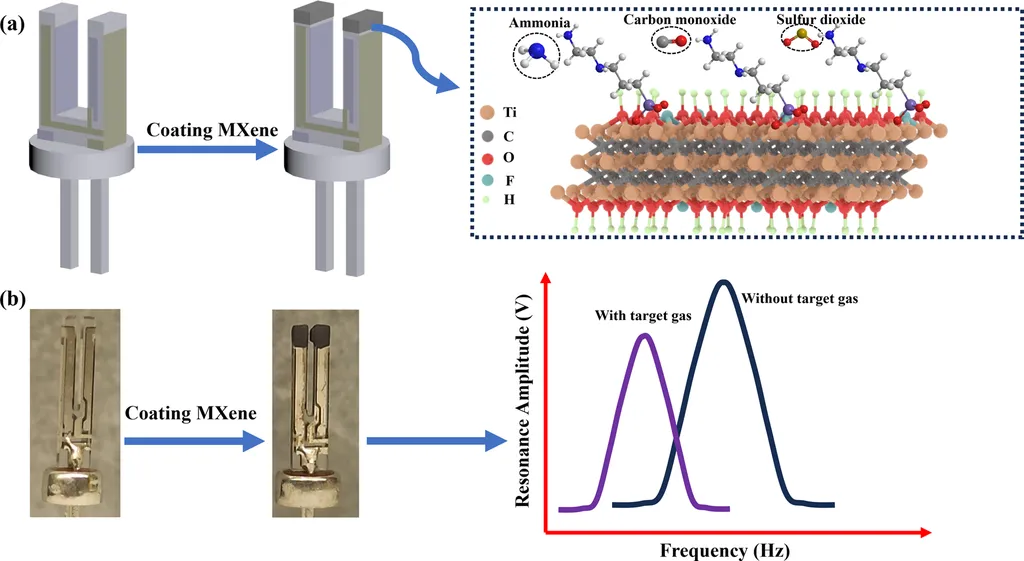

Ammonia detection is crucial for environmental safety and human health, and traditional methods often fall short in terms of sensitivity, selectivity, and response time. Enter MXene-based sensors, which offer a promising solution due to their hierarchical structure, adjustable surface chemical properties, and excellent electrical conductivity. These sensors can operate effectively at low temperatures, making them ideal for a wide range of applications.

“MXene-based sensors have shown remarkable potential in detecting ammonia gas,” said Yiyang Xu, the lead author of the study. “Their unique properties allow for high selectivity, rapid responses, and ultra-low detection limits, even at low temperatures. This makes them highly suitable for industrial safety, food quality monitoring, medical diagnosis, and agricultural management.”

The research team explored various strategies to enhance the sensing performance of MXene composites. These include heterojunction engineering, surface functionalization, and the creation of active sites. Each of these methods plays a crucial role in improving the sensor’s ability to detect ammonia accurately and efficiently.

One of the key challenges addressed in the study is the material’s oxidation resistance and its susceptibility to humidity interference and cross-sensitivity. Overcoming these hurdles is essential for the practical application of MXene-based sensors in real-world scenarios.

The implications of this research are far-reaching, particularly for the energy sector. Ammonia is a significant byproduct in many industrial processes, and its detection is critical for ensuring workplace safety and environmental compliance. The development of highly sensitive and reliable sensors can lead to more efficient monitoring systems, reducing the risk of accidents and improving overall safety standards.

Moreover, the ability to detect ammonia at low temperatures opens up new possibilities for applications in food quality monitoring and medical diagnosis. For instance, in the food industry, ammonia sensors can help detect spoilage and ensure product safety. In the medical field, they can be used to monitor disease biomarkers, providing valuable insights for diagnosis and treatment.

As the world continues to grapple with environmental and health challenges, the need for advanced sensing technologies becomes increasingly apparent. The work of Yiyang Xu and his team represents a significant step forward in this area, offering a glimpse into the future of ammonia detection and its potential impact on various industries.

“Our goal is to achieve real-time and energy-saving environmental and health monitoring networks,” Xu added. “The reasonable design of MXene sensors is a crucial step towards this goal, and we believe that our research will pave the way for more innovative applications in the future.”

In conclusion, the research published in *Micromachines* highlights the potential of MXene-based sensors to revolutionize ammonia detection. By addressing key challenges and exploring innovative design strategies, the team has laid the groundwork for more advanced and reliable sensing technologies. As the world continues to evolve, the need for such technologies will only grow, making this research a vital contribution to the field of environmental and health monitoring.