In the heart of Victoria, Australia, a groundbreaking development is taking root, promising to revolutionize the way we approach agricultural harvesting. Rizan Mohamed, a researcher at Federation University, has introduced a novel soft robotic gripper system designed specifically for the autonomous harvesting of baby broccoli. This innovation, detailed in a recent study published in the journal *Smart Agricultural Technology* (translated from Chinese as *智能农业技术*), addresses critical challenges in the agricultural industry, including labor shortages and the need for efficient, sustainable harvesting solutions.

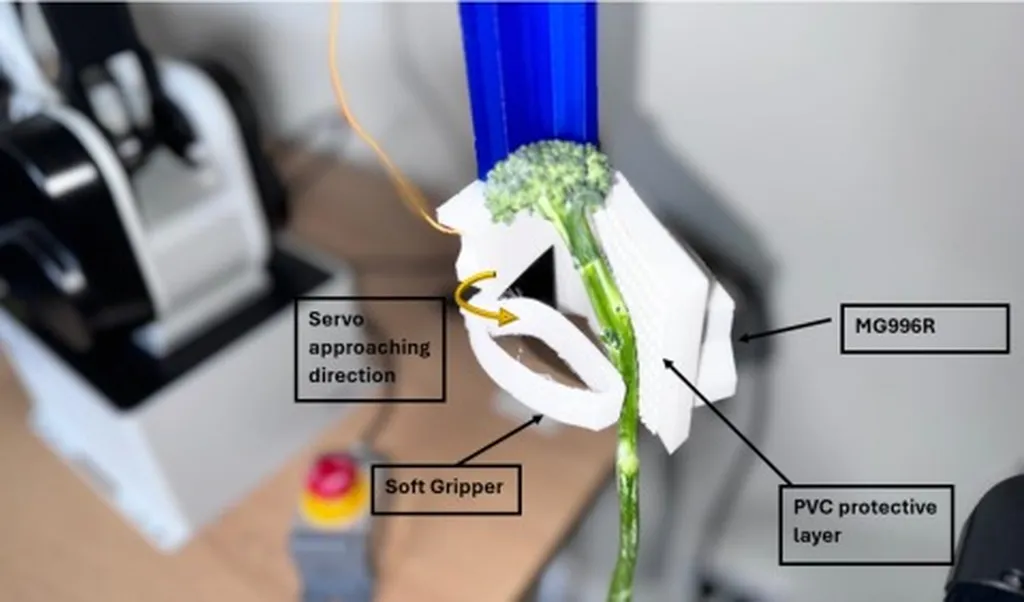

The soft robotic gripper system is a marvel of modern engineering, featuring a flexible gripper fabricated from thermoplastic polyurethane (TPU). This material provides the necessary compliance and durability to handle the delicate stems of baby broccoli without causing damage. “The key to our design is the integration of pressure sensing, which allows the gripper to dynamically adjust grip forces,” explains Mohamed. “This ensures that the grip is secure yet gentle, preventing any harm to the fragile stems during the cutting process.”

The system’s real-time force feedback is a game-changer in the field of agricultural automation. By combining mechanical design optimization with adaptive force control algorithms, the gripper can navigate the variability inherent in agricultural environments. This adaptability is crucial for maintaining optimal harvesting conditions and preserving crop quality.

Field trials have demonstrated the system’s effectiveness, assessing gripping reliability, harvesting speed, and crop damage rates. The results are promising, showcasing the potential for soft robotics and force feedback to automate the harvesting of delicate crops. “Our solution reduces labor dependency while ensuring that the crop quality is maintained,” Mohamed adds. “This is a significant step towards more sustainable and efficient agricultural practices.”

The implications of this research extend beyond the immediate benefits to the agricultural sector. As the world grapples with labor shortages and the need for sustainable practices, innovations like Mohamed’s soft robotic gripper offer a glimpse into the future of farming. The integration of soft robotics and force feedback technologies could pave the way for more efficient and environmentally friendly harvesting methods, reducing the reliance on manual labor and minimizing crop damage.

This development is not just a technological advancement but a testament to the potential of interdisciplinary research. By bridging the gap between mechanical engineering, agricultural science, and robotics, Mohamed and his team have created a solution that addresses real-world challenges. As the agricultural industry continues to evolve, the adoption of such technologies could redefine the landscape of farming, making it more resilient and sustainable.

In the broader context, the soft robotic gripper system exemplifies the potential of soft robotics in various industries. The principles applied in this research could be adapted for other delicate harvesting tasks, from fruits and vegetables to flowers and medicinal plants. The versatility of the system opens up new avenues for automation, reducing labor costs and improving efficiency across the board.

As we look to the future, the work of Rizan Mohamed and his team at Federation University serves as a beacon of innovation. Their research not only addresses current challenges but also sets the stage for future developments in agricultural automation. With the continued advancement of soft robotics and force feedback technologies, we can expect to see more efficient, sustainable, and labor-friendly solutions in the agricultural sector. This is just the beginning of a new era in farming, where technology and nature work hand in hand to create a more sustainable future.