In a significant stride towards a sustainable circular carbon economy, researchers have developed a novel approach to convert carbon dioxide (CO2) into valuable chemicals using modified copper-based zeolite catalysts and microwave plasma technology. This breakthrough, led by Pimchanok Tapangpan from the Department of Industrial Engineering at Chiang Mai University in Thailand, opens new avenues for the energy sector to transform greenhouse gases into useful products, potentially revolutionizing industrial processes and contributing to carbon neutrality goals.

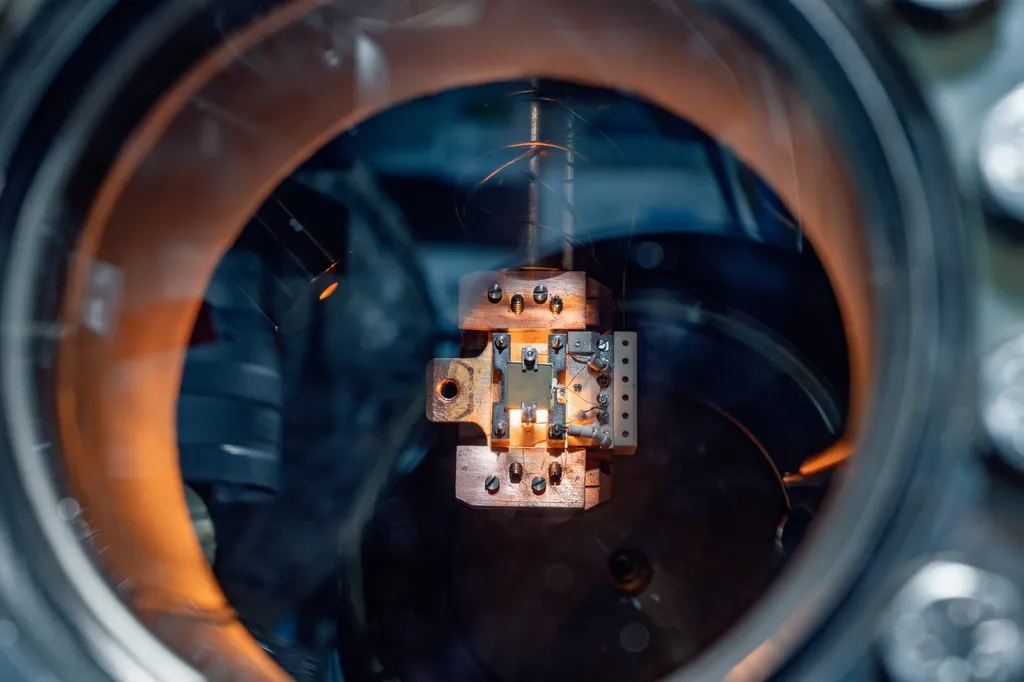

The study, published in *Case Studies in Chemical and Environmental Engineering* (translated as “Case Studies in Chemical and Environmental Engineering”), focuses on enhancing the efficiency of CO2 conversion through the modification of copper (Cu)-based zeolite 13X catalysts. By adjusting the Cu oxidation state and surface basicity using thiourea reduction, the researchers achieved remarkable improvements in the conversion rates and selectivity towards methanol and aromatic compounds like benzene and toluene.

“Our modified catalysts demonstrated a CO2 conversion rate of over 50%, which is a substantial leap compared to the 18.5% conversion achieved with plasma alone,” Tapangpan explained. This enhanced performance not only highlights the effectiveness of the microwave plasma-assisted catalytic process but also underscores the potential for industrial-scale applications.

The research revealed that the synergy between CuI species and surface basicity played a pivotal role in promoting the production of toluene and methanol while minimizing benzene formation. Notably, the study found that catalysts with 0.5 wt% Cu doping and thiourea reduction performed comparably to those with 6 wt% Cu doping without thiourea reduction. This finding emphasizes the economic viability of the thiourea reduction process, as it allows for the production of efficient catalysts with fewer metal precursors.

The implications of this research are profound for the energy sector. By converting CO2 into valuable chemicals such as methanol and aromatics, industries can reduce their carbon footprint while simultaneously creating high-value products. Methanol, for instance, is a versatile chemical used in various applications, including as a fuel additive and in the production of plastics and synthetic materials. Aromatic compounds like benzene and toluene are essential building blocks in the petrochemical industry.

“Our findings suggest that this technology could be scaled up for industrial use, offering a sustainable and economically viable solution for CO2 conversion,” Tapangpan added. The proposed pathways for methanol and aromatic formation provide a roadmap for future developments, potentially leading to innovative processes that integrate CO2 conversion with existing industrial workflows.

As the world seeks to transition towards a greener economy, advancements in CO2 conversion technologies are crucial. This research not only contributes to the scientific understanding of plasma-assisted catalysis but also paves the way for practical applications that can drive the energy sector towards a more sustainable future. With further optimization and scaling, the modified copper-based zeolite catalysts could become a cornerstone in the fight against climate change, transforming CO2 from a greenhouse gas into a valuable resource.