In the heart of China’s agricultural innovation, a groundbreaking study led by Hongjun Wang from the College of Engineering at South China Agricultural University is set to revolutionize the way we approach automated fruit harvesting. The research, published in the esteemed journal *Agronomy* (translated as “Agronomy” in English), tackles the persistent challenges of pineapple harvesting in natural orchard environments, offering a glimpse into the future of agricultural robotics.

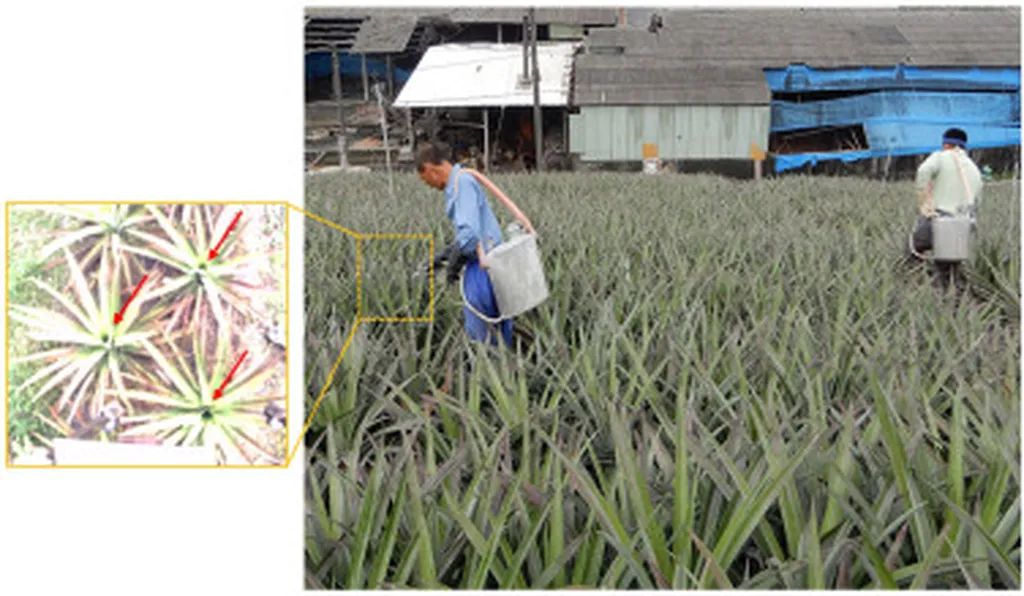

Pineapple harvesting is no easy feat. The dense foliage often leads to high occlusion rates, making it difficult for robotic arms to detect the fruit accurately. Moreover, the cluttered terrain requires complex spatial planning to guide the robotic arm’s movement efficiently. Wang and his team have developed an innovative solution to these problems, combining cutting-edge visual detection and path planning algorithms.

At the core of their solution is the Yolov10n-SSE model, a novel visual detection system that integrates split convolution (SPConv), squeeze-and-excitation (SE) attention, and efficient multi-scale attention (EMA) modules. This advanced model significantly enhances detection accuracy while reducing computational complexity. “Our model achieves notable performance gains in precision, recall, and mean average precision (mAP),” Wang explains. “This means our robotic arms can now detect pineapples with a precision of 93.8% and a recall rate of 84.9%, making the harvesting process much more efficient and reliable.”

But detection is only half the battle. The researchers also tackled the challenge of path planning in cluttered terrains. They developed a dimensionality-reduction strategy that transforms 3D path planning into a more efficient 2D image-space task using point clouds from a depth camera. By combining the artificial potential field (APF) method with an improved RRT* algorithm, they mitigated randomness, ensured obstacle avoidance, and reduced computation time. “Our approach generates collision-free paths, ensuring the stability and safety of the robotic arm’s movement,” Wang adds.

The implications of this research extend far beyond the pineapple orchards. The integration of advanced visual detection and path planning algorithms into robotic systems could revolutionize various sectors, from agriculture to logistics and even energy. Imagine robotic arms that can efficiently navigate and operate in complex environments, reducing human labor and increasing productivity. This could lead to significant cost savings and improved safety standards across industries.

Moreover, the scalability of this approach means it can be adapted to other fruits and even non-agricultural applications. “Our solution addresses key bottlenecks in agricultural robotics and fosters advancements in fruit-picking automation,” Wang notes. “This is just the beginning. The potential for this technology is vast and varied.”

As we look to the future, the work of Wang and his team offers a promising path forward. Their research not only enhances the efficiency and reliability of automated pineapple harvesting but also paves the way for broader advancements in robotic technology. The integration of deep learning and path planning algorithms into robotic systems is a significant step towards a more automated and efficient future. And with the publication of their findings in *Agronomy*, the agricultural and robotic communities now have a robust framework to build upon, driving innovation and progress in the field.

In the ever-evolving landscape of agricultural technology, this research stands as a testament to the power of innovation and the potential for robotic systems to transform industries. As we continue to explore and develop these technologies, the future of automated harvesting and beyond looks brighter than ever.