In the heart of Xinjiang, China, a team of researchers led by Dr. Liu Enhui from Xinjiang University has made a significant stride in the field of agritech, particularly in the realm of vegetable oil preservation. Their study, published in the journal *Shipin Kexue* (which translates to *Food Science*), focuses on the creation of blended walnut oil (BWO) microcapsules using a complex coacervation method. This innovative approach aims to enhance the oxidative stability of vegetable oils, a critical factor in the food processing industry.

The research team, which includes members from the Xinjiang Key Laboratory of Biological Resources Genetic Engineering and the Xinjiang Walnut Industry Engineering Technology Research Center, explored the use of walnut protein isolate (WPI) combined with different polysaccharides—gum arabic (GA), sodium alginate (SA), or carboxymethyl cellulose sodium (CMC)—to form the microcapsules. The optimal ratios of protein to polysaccharide and the precise pH levels for each combination were meticulously determined using zeta potential and turbidity measurements.

Dr. Liu Enhui explained, “The goal was to find the perfect balance between the protein and polysaccharide to create a stable and effective microcapsule that could encapsulate the walnut oil. The results were promising, with the WPI:GA combination showing the highest encapsulation efficiency and solubility.”

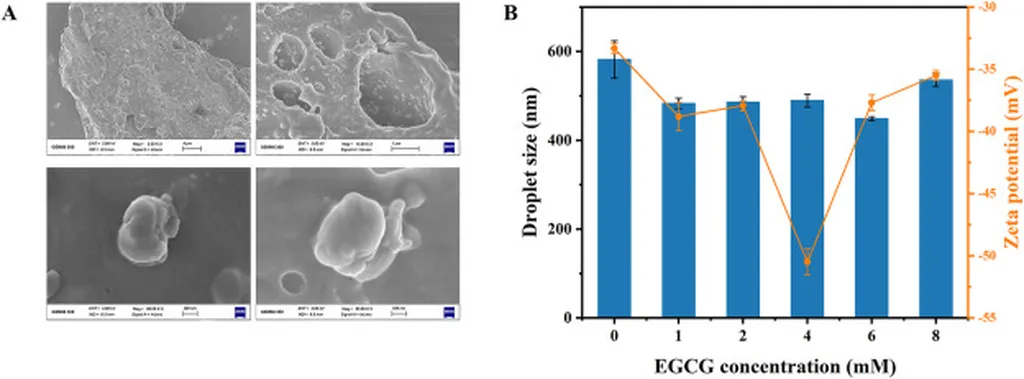

The study revealed that the microcapsules with a WPI:GA ratio of 4:1 at pH 4.3 exhibited the highest encapsulation efficiency (94.02%) and solubility (84.49%), with an average particle size of 226.70 μm. Infrared spectroscopy confirmed the formation of coacervates through electrostatic interactions, which are crucial for encapsulating the blended oils. X-ray diffraction (XRD) analysis further showed that these microcapsules had high relative crystallinity, indicating their structural integrity.

One of the most compelling aspects of this research is its potential impact on the food processing industry. The enhanced oxidative stability of vegetable oils can significantly extend their shelf life, reducing waste and improving product quality. This is particularly relevant in the context of sustainable agriculture and food security.

Dr. Niu Qing, another key member of the research team, added, “The thermal stability of these microcapsules below 250 ℃ is another critical factor. It ensures that the encapsulated oils can withstand various processing conditions without degrading, making them suitable for a wide range of applications.”

The implications of this research extend beyond the food industry. The techniques and insights gained from this study could be adapted for other vegetable oils, potentially revolutionizing the way we preserve and utilize these valuable resources. As the world continues to seek sustainable and efficient solutions for food preservation, the work of Dr. Liu Enhui and his team offers a promising avenue for future developments.

In summary, this groundbreaking research not only advances our understanding of microencapsulation techniques but also paves the way for innovative applications in the food processing industry. The findings published in *Shipin Kexue* provide a robust theoretical foundation for the development of powdered walnut oil products and the effective protection of vegetable oils, broadening the application scope of walnut oil in various sectors.