In the heart of Lahore, Pakistan, a groundbreaking study is challenging the status quo of construction materials, with potential ripples extending into the energy sector. Hafiz Muhammad Shahzad Aslam, a researcher from the Department of Technology at The University of Lahore, has been delving into the world of sand—an unassuming yet crucial component in cementitious mortar. His work, published in the journal *Results in Engineering* (translated from the original Persian title), is shedding new light on how milling and gradation of Lawrencepur sand can significantly enhance mortar performance, offering a promising alternative to traditional sand sources.

The swift pace of urbanization and industrialization has put immense pressure on natural sand resources, leading to environmental degradation and a scarcity of suitable materials. “We’re facing a dual crisis,” Aslam explains. “On one hand, we’re depleting our natural sand resources at an alarming rate, and on the other, we’re grappling with the accumulation of industrial waste.” His research aims to address these challenges by exploring the potential of Lawrencepur sand, a locally available resource that has often been overlooked due to its fine texture and poor grading.

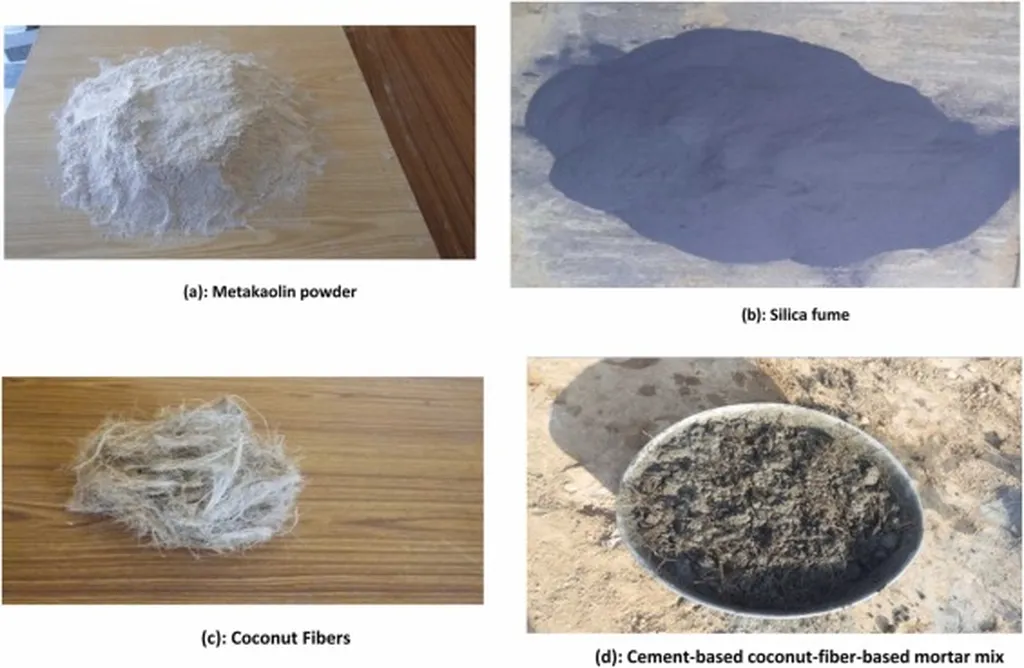

Aslam’s comprehensive study involved milling Lawrencepur sand to different gradation sizes and evaluating its impact on the physical properties of the sand and the mechanical performance of mortar. The results were striking. Milling refined the sand’s physical properties, decreasing size, fineness modulus, and absorption, while increasing density and specific gravity. These improvements translated into enhanced mortar performance, with milled sand boosting mortar density by up to 11.5%, compressive strength by up to 71.4%, and flexural strength by up to 48%. Moreover, water absorption was reduced by up to 34%, a critical factor in the durability of construction materials.

However, Aslam’s research also revealed that there’s a fine line between enhancement and detriment. “Excessive milling can lead to a decline in performance due to poor packing,” he cautions. This nuanced understanding is crucial for practical applications, ensuring that the benefits of milling are maximized without compromising the material’s integrity.

The implications of this research extend beyond the construction industry. In the energy sector, where infrastructure development is constant, the demand for high-quality, sustainable building materials is paramount. Aslam’s findings could pave the way for more efficient and eco-friendly construction practices, reducing the environmental footprint of energy projects.

Statistical analysis using SPSS confirmed the significant improvement in mortar performance with milled sand, with strong statistical validation (p < 0.001). Furthermore, Scanning Electron Microscopy (SEM) and X-ray Diffraction (XRD) analysis provided microstructural evidence of the mortar's densification through milling, reinforcing the study's findings.Aslam's research is not just about improving sand quality; it's about rethinking our approach to resource utilization. By harnessing the potential of locally available materials like Lawrencepur sand, we can mitigate the environmental impact of construction and energy projects, fostering a more sustainable future. "This is just the beginning," Aslam says. "The possibilities are vast, and the potential for innovation is immense."In a world grappling with resource depletion and environmental degradation, Aslam's work offers a beacon of hope. It's a testament to the power of innovative thinking and the potential of local solutions to global challenges. As the energy sector continues to evolve, research like this will be instrumental in shaping a more sustainable and efficient future.