In the heart of Tokyo, a groundbreaking study led by Tomoki Takano from the Graduate School of Agricultural and Life Sciences at the University of Tokyo is revolutionizing the way we think about edamame production. The research, published in the esteemed journal *Scientific Reports* (translated to English as “Scientific Reports”), explores the potential of plant factories using artificial light to cultivate this nutritious legume year-round, with significant implications for the agricultural and energy sectors.

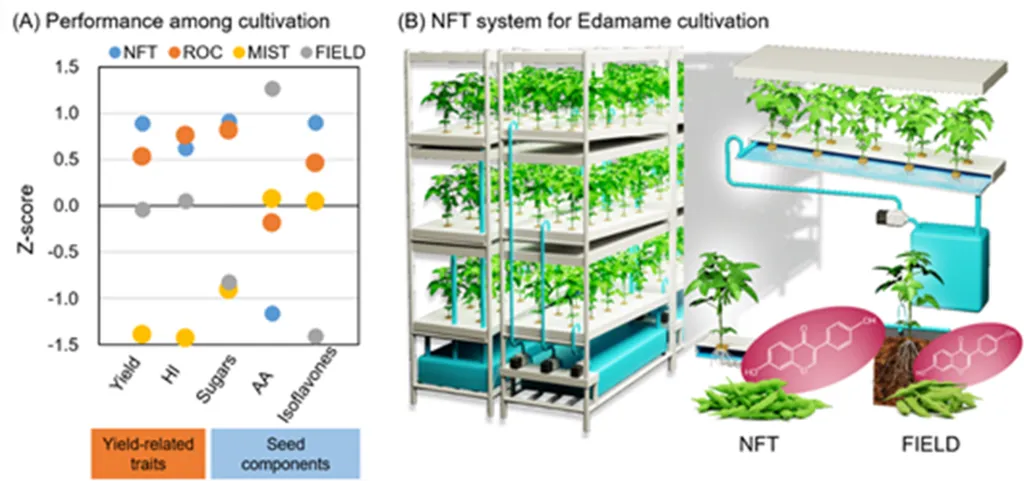

Edamame, a popular and protein-rich legume, has traditionally been constrained by seasonal availability due to challenges in long-term storage. However, Takano’s study demonstrates that edamame can thrive in controlled environments, offering a sustainable solution to meet global demand. The research team employed three hydroponic systems—nutrient film technique (NFT), rockwool, and aeroponics (mist culture)—within an LED plant factory. Among these, the NFT system stood out, yielding fresh seed weights comparable to or even exceeding those achieved through conventional field cultivation.

“The NFT system not only matched but in some cases surpassed the yield of traditional field cultivation,” Takano explained. “This is a significant breakthrough, as it opens up new possibilities for edamame production in urban and even space agriculture.”

The success of the NFT system can be attributed to enhanced pod formation and biomass production under controlled conditions. While the free amino acid content was lower in NFT-grown edamame, the plants exhibited significantly higher total sugar and isoflavone contents compared to their field-grown counterparts. Isoflavones, known for their health benefits, are a key selling point for edamame, making this discovery particularly noteworthy for the commercial sector.

“This research is not just about increasing yield; it’s about enhancing the nutritional profile of edamame,” Takano added. “Higher isoflavone content means better health benefits for consumers, which can drive market demand and open new avenues for commercialization.”

The implications of this study extend beyond the agricultural sector. Plant factories utilizing artificial light offer a sustainable and efficient model for crop production, reducing the need for vast expanses of land and minimizing environmental impact. This aligns with the growing global emphasis on sustainability and the need for innovative solutions to feed a burgeoning population.

Moreover, the energy sector stands to benefit from the integration of plant factories into urban landscapes. These facilities can be powered by renewable energy sources, contributing to a greener future. The potential for year-round production also means a more stable supply chain, reducing the reliance on seasonal harvests and mitigating the risks associated with climate change and unpredictable weather patterns.

As the world grapples with the challenges of climate change and food security, Takano’s research offers a beacon of hope. The successful cultivation of edamame in controlled environments paves the way for similar advancements in other crops, potentially transforming the agricultural landscape. The study not only highlights the potential of plant factories but also underscores the importance of interdisciplinary collaboration in driving innovation.

In the words of Takano, “This is just the beginning. The possibilities are vast, and the potential for impact is immense. We are on the cusp of a new era in agriculture, one where technology and sustainability go hand in hand.”

As the world continues to evolve, so too must our approaches to food production. Takano’s research is a testament to the power of innovation and the potential for technology to address some of the most pressing challenges of our time. The future of agriculture is here, and it is shining brightly in the form of LED-lit plant factories.