The daily rhythm of farm work is changing. At the University of Wisconsin-Madison Extension, specialists are watching as technology and automation redefine how farms operate—not as a distant promise, but as a present reality. A little over a century ago, farming depended on human labor, horsepower, and the first clanking tractors. Today, robotic milkers, automated feeders, and driverless tractors are taking over tasks across Wisconsin and the Midwest. Elsewhere, robots pick fruit, lasers zap weeds, and drones scout fields. The shift isn’t just about novelty; it’s about filling labor gaps, cutting costs, and working with greater precision.

Yet for all the potential, success hinges on more than just buying the latest machine. It starts with a plan.

**From Hands to Algorithms**

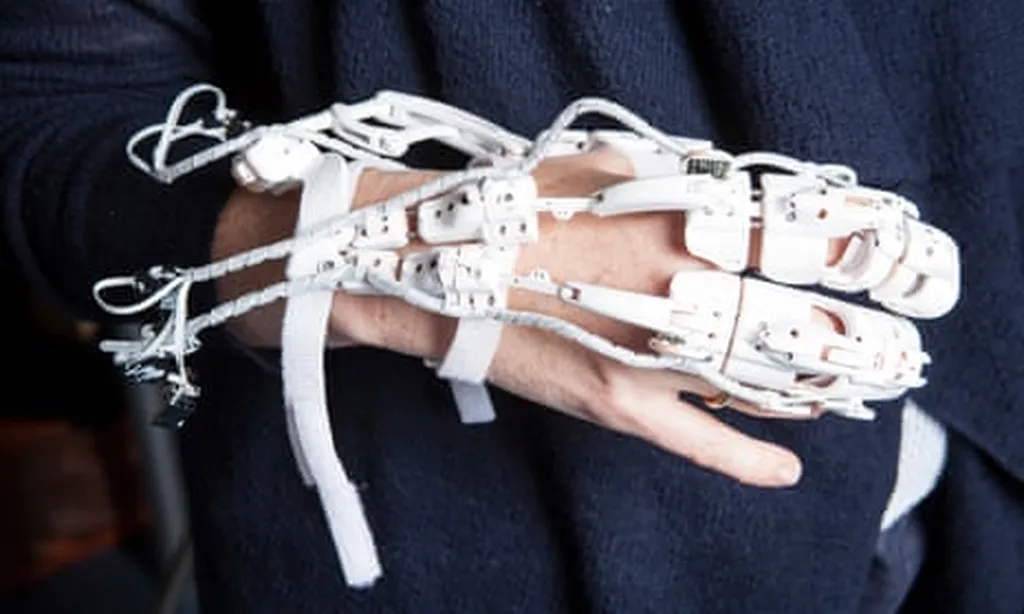

Automation’s core appeal is straightforward: it replaces physical and mental strain with sensors, software, and steel. Whether it’s a robotic milker reducing the grind of twice-daily milking or a self-steering tractor easing 14-hour days in the cab, the goal is to save time, spare bodies, and reduce the injuries and stress that come with farm work.

But broader pressures are pushing farms toward technology. Labor shortages persist—fewer workers are willing or available to take on the demanding, often isolating work of agriculture. Those who do stay can face burnout, making it harder for farms to keep skilled help. Meanwhile, input costs keep climbing, squeezing margins. Automated systems, with their ability to monitor individual animals or tailor fertilizer to precise patches of a field, offer a way to stretch resources further.

Yet the transition isn’t as simple as flipping a switch. The wrong investment can drain finances without delivering results. That’s why UW-Madison Extension emphasizes a deliberate approach, starting with two fundamental questions: *Why* automate, and *what* does the farm’s current operation truly look like?

**The “Why” Behind the Tech**

Before purchasing anything, producers need to define their motivations. Is the goal to eliminate a hated task—like hauling heavy feed bales or working in extreme heat? To retain family members who might otherwise leave the farm? To protect long-term health after decades of wear and tear? Or to expand production without adding labor?

Each reason carries different implications. A farm struggling to hire workers might prioritize labor-saving tech, while one focused on succession planning could invest in systems that make the work more appealing to the next generation. Some producers may simply want to reduce their own 80-hour workweeks. Others see automation as a path to higher profitability through lower costs or increased output.

Whatever the driver, clarity is key. “Don’t buy technology just because it’s interesting,” advises the Extension. “Buy it because it solves a specific problem.”

**Numbers, Not Guesses**

Once the “why” is clear, the next step is data. Producers need hard numbers on how work is done now—labor hours, costs per acre or per animal, energy use, repair expenses—and how those metrics fluctuate across seasons and market conditions.

For example, a dairy considering robotic milkers must compare current labor costs and milking times against the system’s upfront price, energy demands, and potential changes in milk quality or cow health. A grain farm eyeing an autonomous sprayer needs to weigh fuel savings against the machine’s depreciation and the risk of downtime during critical windows.

Vendors may offer rosy projections, but farms must run their own calculations. Automation often shifts costs from variable (like hourly wages) to fixed (like equipment loans and maintenance), meaning financial risks change too. A spike in electricity rates could alter the math for an automated feeding system, just as a labor shortage might suddenly make a high-priced robot look like a bargain.

The takeaway? Technology is reshaping farming, but its value depends on how well it aligns with a farm’s real needs—and whether the numbers add up. The tools are here; the challenge is using them wisely.