In the heart of India’s agricultural landscape, a critical issue has been gaining attention: the health and safety of tractor operators. A recent study, led by Sandeep Rajan Nagarajan from the Department of Automotive Engineering at Vellore Institute of Technology, has shed light on the exposure of tractor operators to Whole-Body Vibration (WBV), Hand-Arm Vibration (HAV), and noise, publishing its findings in the journal ‘Results in Engineering’ (which translates to ‘Results in Engineering’ in English). The research not only quantifies these exposures but also offers a novel approach to optimizing measurements, potentially revolutionizing safety standards in the agricultural sector.

The study, which involved measuring acceleration and noise at various points on the tractor and operator, revealed that while WBV levels posed a moderate risk, HAV levels were within safe limits. However, the noise levels were alarmingly high, ranging from 122 dB(A) to 124 dB(A) under different operating conditions. “The operator is subjected to higher noise levels, which is a significant concern,” Nagarajan noted, emphasizing the urgent need for intervention.

The commercial implications of this research are substantial. Tractors are the backbone of the agricultural industry, and ensuring the health and safety of operators directly impacts productivity and efficiency. High noise levels can lead to hearing loss and fatigue, while prolonged exposure to vibrations can cause musculoskeletal disorders. By addressing these issues, farmers can expect improved operator health, reduced downtime, and increased productivity.

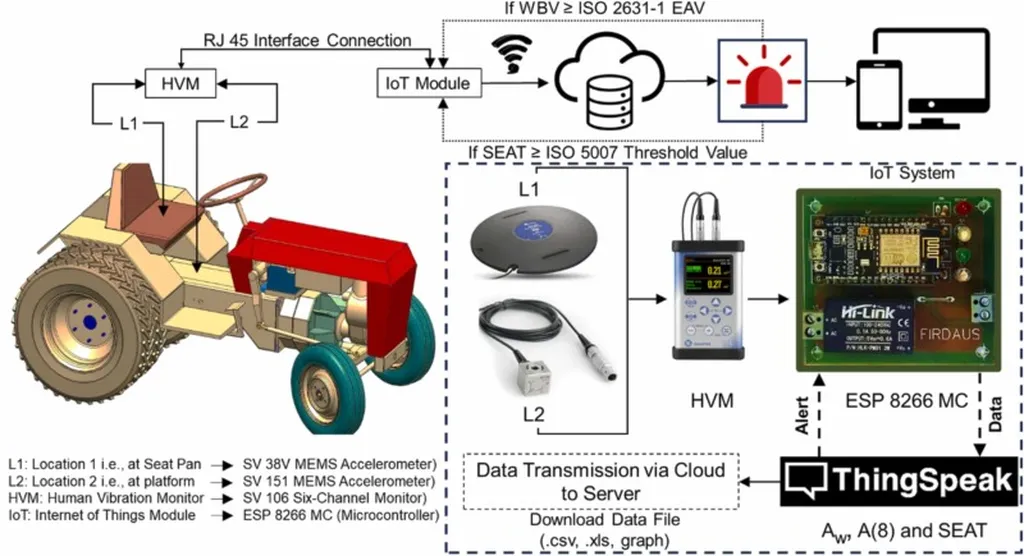

Moreover, the novel approach proposed by Nagarajan and his team could make a significant difference in the field. By optimizing the number of channels used for measurements, the study suggests a more efficient and cost-effective way to monitor and assess tractor operators’ exposure to vibrations and noise. This could lead to more widespread adoption of safety measures, as it reduces the burden on farmers and manufacturers.

The research also opens up avenues for future developments. As Nagarajan explains, “The limited number of channels used wisely to check the repeatability of the measurements is a novel approach.” This could pave the way for more advanced and accurate monitoring systems, further enhancing operator safety.

In the broader context, this study highlights the importance of integrating safety and health considerations into the design and operation of agricultural machinery. It serves as a call to action for manufacturers, policymakers, and farmers to prioritize operator safety and well-being. As the agricultural sector continues to evolve, so too must its approach to health and safety, ensuring a sustainable and productive future for all involved.

In the meantime, Nagarajan and his team’s work stands as a testament to the power of innovative research in driving meaningful change. Their findings, published in ‘Results in Engineering’, offer a crucial step forward in safeguarding the health of tractor operators, ultimately benefiting the entire agricultural sector.