In the heart of Vietnam, at RMIT University, a groundbreaking study led by Hieu M. Tran is revolutionizing the way we think about avocado processing. The research, published in *Scientific Reports* (which translates to *Nature Research Journal*), is not just about avocados; it’s about precision, efficiency, and the future of agricultural engineering.

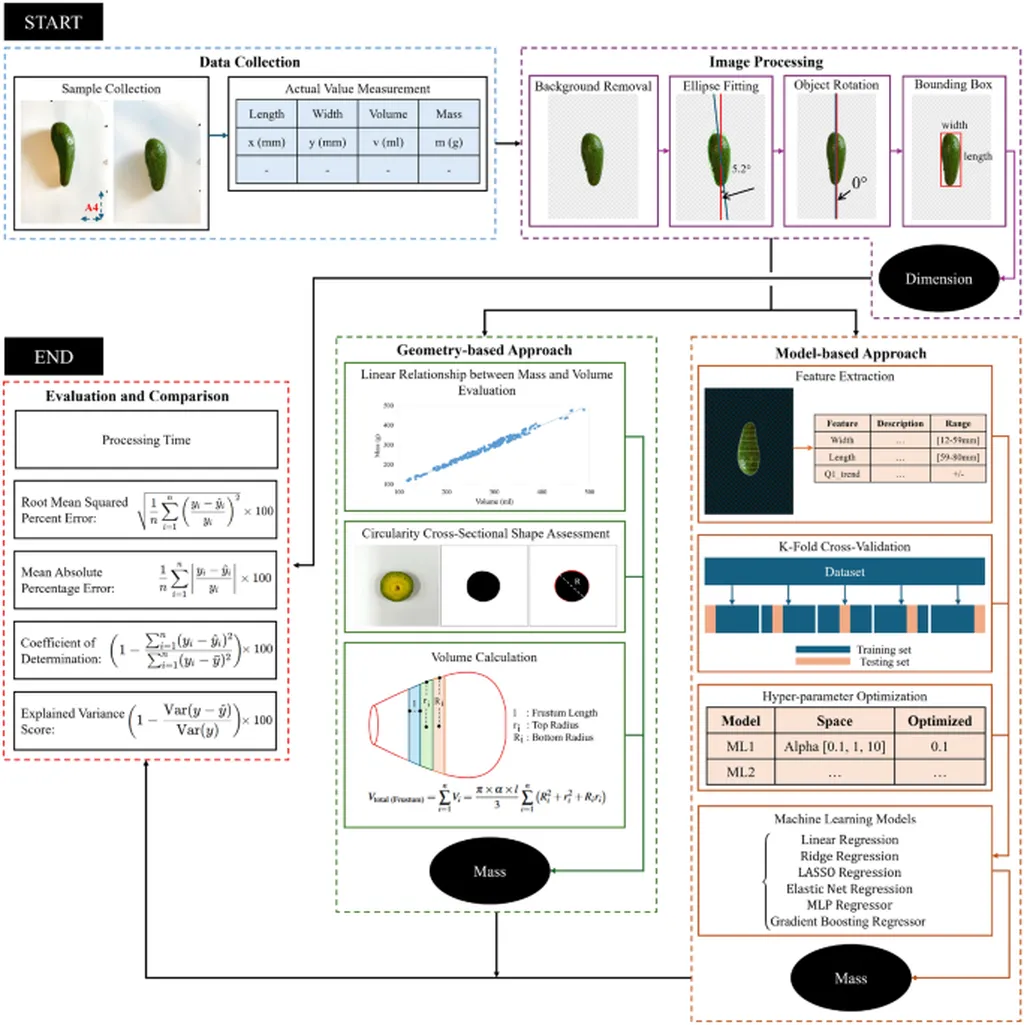

Tran and his team have been working on a systematic review and comparison of geometry-based and regression model-based techniques to accurately estimate the physical properties of avocados, particularly their mass. This might sound like a niche area, but the implications are vast, especially for the agricultural and food engineering industries.

The study found that the Frustum method consistently outperformed other approaches across all slice configurations. “The Frustum method achieved the lowest errors with a Root Mean Square Percentage Error (RMSPE) of 4.24% and a Coefficient of Determination (R²) value of 97.78% at 20 slices,” Tran explains. This method’s robustness and reliability make it a game-changer for precise mass estimation, even without requiring large datasets or complex computations.

But the story doesn’t end there. Regression-based methods, such as Ridge Regression, also exhibited strong performance. “Ridge Regression had an average RMSPE of 4.30% and an R² of 97.71% across 5 folds at 15 slices,” Tran adds. This makes it a competitive and stable alternative, especially when considering the variability between folds seen in other models like MLP Regressor and Gradient Boosting Regressor.

The study also assessed the dimensions of avocados, with error rates below 1.53% and model-fit parameters of over 99%. This high accuracy in determining both the width and length of the avocado opens up new possibilities for automation in precision agriculture and modern intelligent food processing systems.

So, what does this mean for the future? The findings provide a comparative perspective on the choice of forward models depending on task characteristics, including dataset availability, stability, and precision level. This research could shape the development of state-of-the-art automation technologies, particularly in robotic harvesting and grading solutions.

As we look ahead, the work of Hieu M. Tran and his team at RMIT University Vietnam serves as a beacon of innovation. It’s a reminder that even in the most unexpected places, groundbreaking research is happening, pushing the boundaries of what’s possible in agricultural engineering and food processing. The future is here, and it’s delicious, efficient, and precisely measured.