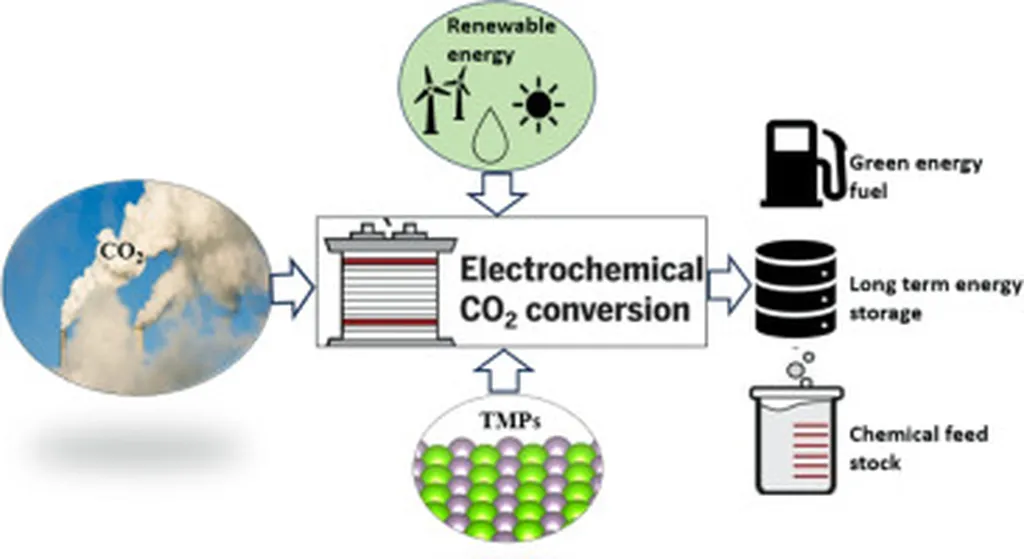

In the quest to combat climate change and transition towards a sustainable energy future, scientists are exploring innovative ways to convert carbon dioxide (CO2) into valuable products. A recent comprehensive review published in the journal *Nano Materials Science* (translated to English as *Nanomaterials Science and Technology*) sheds light on the advancements in electrochemical CO2 conversion, offering promising avenues for the energy sector.

The review, led by Shahid Ashraf from the Department of Physics at the University of Agriculture Faisalabad in Pakistan, delves into the production of methanol, ethanol, and n-propanol using various catalysts. These catalysts range from metals and metal oxides to metal alloys and metal-organic frameworks. The primary goal is to identify efficient electrocatalysts that prioritize selectivity, stability, Faradaic efficiency (FE), and current density.

One of the notable catalysts mentioned in the review is the PtxZn nanoalloys, which exhibit an impressive FE of approximately 81.4% for methanol production. “The development of these nanoalloys represents a significant step forward in our quest for efficient CO2 conversion,” says Ashraf. Another promising catalyst is the trimetallic Pt/Pb/Zn nanoalloys, which aim to reduce the cost of platinum while enhancing catalyst stability and durability.

Metal oxide catalysts like thin film Cu2O/CuO on nickel foam and Cu2O/ZnO also show promising results, with FE values of approximately 38% and 16.6% for methanol production, respectively. Copper-based metal-organic frameworks, such as Cu@Cu2O, demonstrate an FE of approximately 45% for methanol production. For ethanol production, Ag0.14/Cu0.86 and Cu–Zn alloys exhibit FEs of approximately 63% and 46.6%, respectively. Notably, n-propanol production via Pd–Cu alloy and graphene/ZnO/Cu2O yields FEs of approximately 13.7% and 23%, respectively.

The review also discusses recent advancements in photoelectrochemical (PEC) reactor design, photoelectrodes, reaction mechanisms, and catalyst durability. By evaluating the efficiency of these devices in liquid fuel production, the review addresses the challenges and prospects in CO2 conversion for obtaining various valuable products.

The implications of this research for the energy sector are profound. Efficient CO2 conversion technologies can help reduce greenhouse gas emissions while simultaneously producing valuable chemicals and fuels. This dual benefit makes the technology particularly attractive for commercial applications. As the world moves towards a low-carbon economy, the ability to convert CO2 into useful products could play a pivotal role in mitigating climate change and ensuring energy security.

The research highlights the importance of continued innovation in catalyst design and reactor technology. As Ashraf notes, “The future of CO2 conversion lies in our ability to develop more efficient and cost-effective catalysts. This will not only enhance the economic viability of the process but also contribute to a more sustainable future.”

In conclusion, the review published in *Nano Materials Science* offers a comprehensive overview of the current state and future prospects of electrochemical CO2 conversion. The findings underscore the potential of this technology to revolutionize the energy sector and contribute to global efforts to combat climate change. As research in this field continues to evolve, the prospects for efficient and sustainable CO2 conversion become increasingly bright.