In the world of herbal pharmaceuticals, standardization is the cornerstone of quality and efficacy. A recent study published in *Advances in Food Science, Sustainable Agriculture, and Agroindustrial Engineering* sheds light on the standardization of Moringa oleifera leaf powder extracts, a promising raw material for pharmaceutical applications. The research, led by Ambar Fidyasari from Universitas Brawijaya, explores how variations in leaf stalk color—green, white, and red—affect the extract’s yield, quality, and compliance with pharmaceutical standards.

The study found that the red-stalked Moringa oleifera leaf powder (MOLP) yielded the highest extract when processed with ethanol, a key finding for farmers and processors aiming to maximize output. “The color of the leaf stalk is not just a visual difference; it significantly impacts the extract yield and quality,” Fidyasari explained. This discovery could guide agricultural practices, encouraging the cultivation of red-stalked Moringa varieties to enhance productivity and profitability.

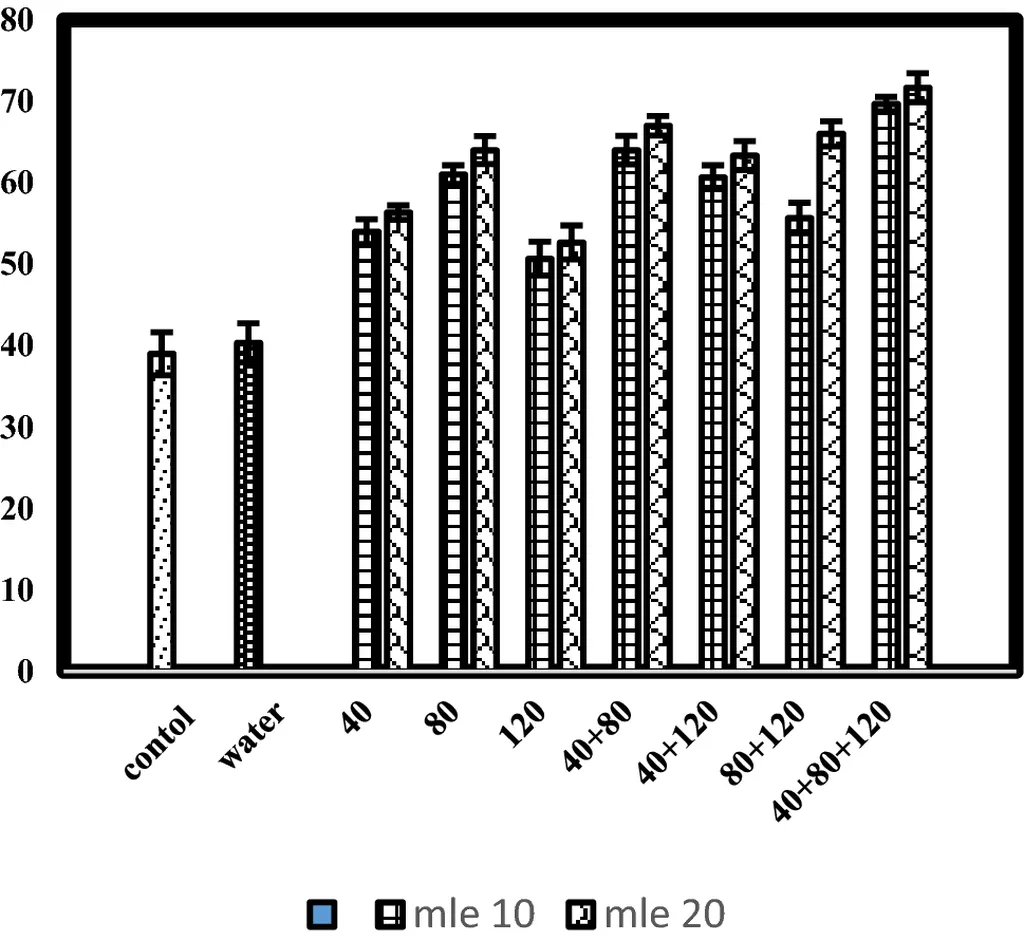

The organoleptic analysis revealed that the extracts were thick, greenish-brown, with a characteristic odor and bitter taste—a profile that could influence consumer acceptance and marketability. The study also confirmed that the water-soluble and ethanol-soluble extract contents met the standard of ≥ 5.0%, a crucial benchmark for pharmaceutical applications.

Non-specific parameters such as loss on drying, total ash content, acid-insoluble ash content, and extract specific gravity all met the required standards, ensuring the extracts’ stability and purity. Microbial contamination was also within acceptable limits, below the maximum of 10 colonies per gram, a critical factor for safety and regulatory compliance.

The chromatographic profile obtained through Gas Chromatography-Mass Spectrometry (GC-MS) identified the presence of terpenoids and steroids in the extracts, compounds known for their pharmacological potential. “These findings not only validate the quality of Moringa oleifera extracts but also open avenues for further research into their therapeutic applications,” Fidyasari noted.

The study’s adherence to the Indonesian Pharmacopoeia standards underscores its relevance for the pharmaceutical industry, particularly in regions where Moringa oleifera is widely cultivated. For the agriculture sector, this research could drive the development of specialized cultivation practices, quality control measures, and value-added processing techniques. As the demand for natural and herbal pharmaceuticals continues to grow, the standardization of Moringa oleifera extracts could pave the way for new commercial opportunities and enhanced agricultural productivity.

This research not only advances our understanding of Moringa oleifera but also highlights the importance of standardization in bridging the gap between traditional herbal remedies and modern pharmaceutical applications. As Fidyasari and her team continue to explore the potential of this versatile plant, the agricultural and pharmaceutical industries stand to benefit from these groundbreaking insights.