In the quest for sustainable agriculture, biochar has emerged as a promising tool, offering benefits such as improved soil health and carbon sequestration. However, predicting the yield of biochar from biomass pyrolysis has been a complex challenge due to the multitude of interacting factors involved. A recent study published in *Energy Exploration & Exploitation* tackles this issue head-on, offering a novel approach to optimize biochar production.

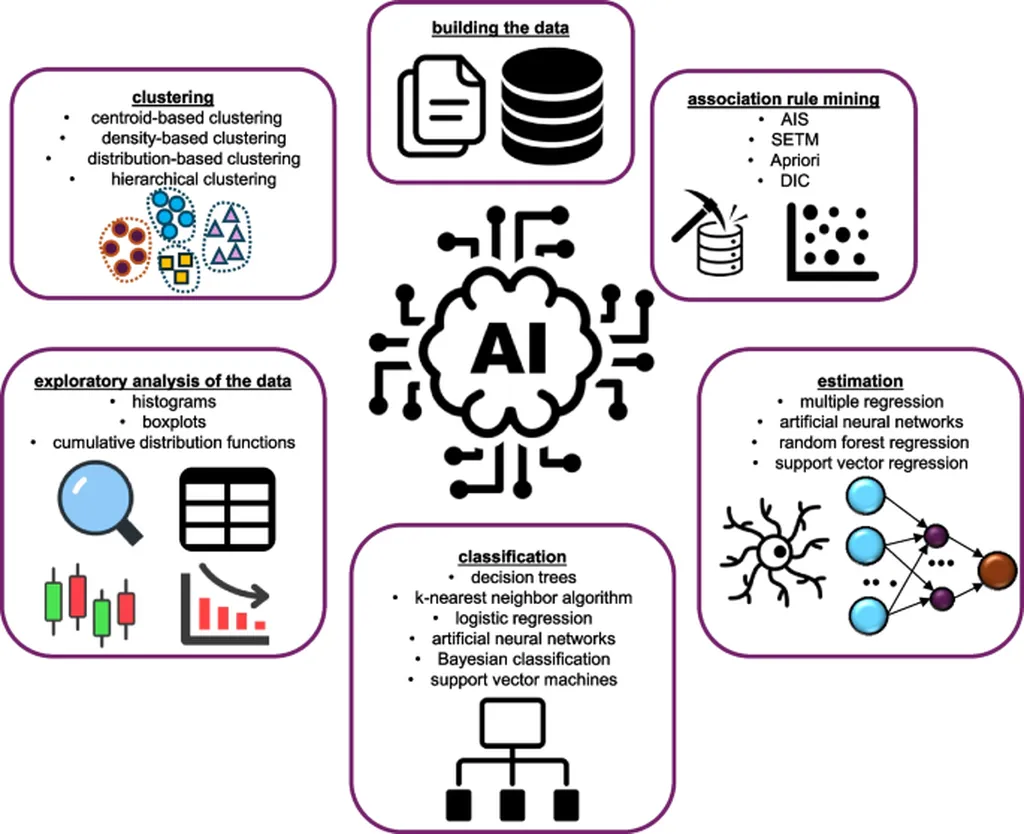

The research, led by Walid Abdelfattah from the Department of Mathematics at the College of Science in Arar, Saudi Arabia, developed a predictive framework using a curated dataset of 211 samples. Each sample included 14 normalized input features—ranging from chemical composition to physical properties and operational parameters—and one output variable: biochar yield. The team employed machine learning modeling, specifically Gradient Boosted Decision Trees (GBDT), to build their predictive models.

To ensure the models’ accuracy, the researchers exhaustively tuned the hyperparameters using various optimization techniques: Gaussian Processes Optimization (GPO), Evolutionary Strategies (ES), Bayesian Probability Improvement (BPI), and Batch Bayesian Optimization (BBO). The models were then evaluated on a train-test split, with the GBDT–BPI model achieving the best performance.

“Our study demonstrates that machine learning can be a powerful tool in predicting biochar yield,” said Abdelfattah. “By understanding and optimizing the key parameters, we can significantly enhance the efficiency of biochar production, making it a more viable option for sustainable agriculture.”

The commercial implications for the agriculture sector are substantial. Accurate prediction of biochar yield can lead to optimized production processes, reducing costs and improving the quality of biochar. This, in turn, can enhance soil health, increase crop yields, and contribute to carbon sequestration efforts.

The study also identified the top parameters influencing biochar yield: reside duration, temperature, and fixed carbon. This insight can guide farmers and biochar producers in fine-tuning their processes for maximum efficiency.

Looking ahead, this research could shape future developments in the field by encouraging the adoption of machine learning techniques in agricultural processes. As Abdelfattah noted, “The integration of data science and agriculture has immense potential. Our work is just the beginning.”

The study’s diagnostic leverage analysis further underscored the high quality of the data used, with less than 1% flagged as influential outliers. This robustness adds confidence to the findings and their potential applications.

In conclusion, this research represents a significant step forward in optimizing biochar production. By leveraging machine learning and advanced optimization techniques, it paves the way for more sustainable and efficient agricultural practices. As the world continues to seek solutions for sustainable agriculture, studies like this one offer valuable insights and tools for the future.