In the ever-evolving landscape of food safety and agricultural technology, a groundbreaking development has emerged that promises to revolutionize the way we ensure the quality of fresh-cut vegetables. Researchers have unveiled an intelligent inspection system that leverages the power of deep learning to detect foreign materials (FM) in real-time, offering a robust solution to a persistent challenge in the food processing industry.

The study, published in the journal *Agriculture*, introduces a system built on the YOLO (You Only Look Once) object detection framework, specifically utilizing YOLOv7. This advanced technology is designed to identify a wide array of foreign materials, from transparent plastics and small stones to insects, all of which can pose significant risks to consumer health and product quality.

“Ensuring food safety is paramount, and the presence of foreign materials in fresh-cut vegetables is a critical concern,” said Hary Kurniawan, lead author of the study and a researcher at the Department of Smart Agricultural System, College of Agricultural and Life Science, Chungnam National University in the Republic of Korea. “Our system addresses this issue by providing a highly accurate, real-time detection mechanism that can be seamlessly integrated into existing processing lines.”

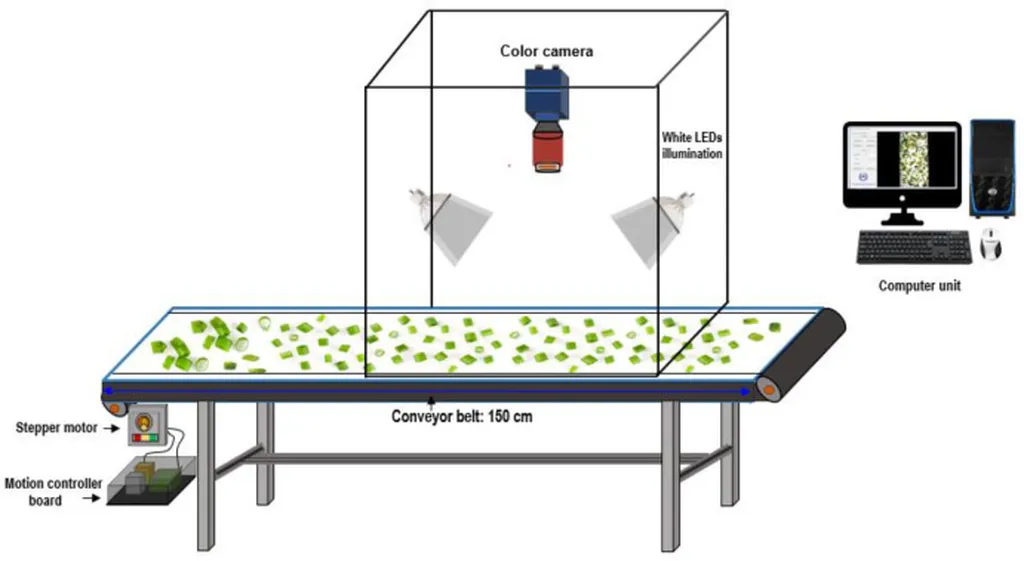

The research team trained six different YOLO variants on a custom dataset comprising 14 categories of foreign materials, varying in shapes, sizes, and colors. Among these, YOLOv7x stood out, demonstrating exceptional accuracy in detecting even the most challenging objects. The system was further integrated with a conveyor-based inspection setup and a user-friendly Python graphical interface, ensuring stable and high detection accuracy in real-world scenarios.

The implications of this research for the agriculture sector are profound. By automating the inspection process, the system not only enhances food safety but also improves efficiency and reduces the need for manual labor. This can lead to significant cost savings for food processing companies and ensure a higher standard of quality control.

“Our goal is to establish a solid foundation for future robotic-based removal systems aimed at fully automated food safety assurance,” Kurniawan added. “This technology has the potential to transform the way we approach quality control in the food industry, making it more efficient, reliable, and safe for consumers.”

As the agriculture sector continues to embrace technological advancements, this intelligent inspection system represents a significant step forward. It not only addresses immediate concerns related to food safety but also paves the way for further innovations in automated quality control. The research, led by Hary Kurniawan and his team at Chungnam National University, underscores the importance of integrating cutting-edge technology into agricultural practices to meet the growing demands for safety and efficiency in the food industry.