In the quest to reduce food waste and improve post-harvest quality management, researchers have developed a novel, non-destructive method for assessing kiwifruit firmness using vibration analysis and machine learning. This innovative approach, published in *Smart Agricultural Technology*, could revolutionize the way the agriculture sector monitors and manages fruit quality, ultimately leading to significant economic and environmental benefits.

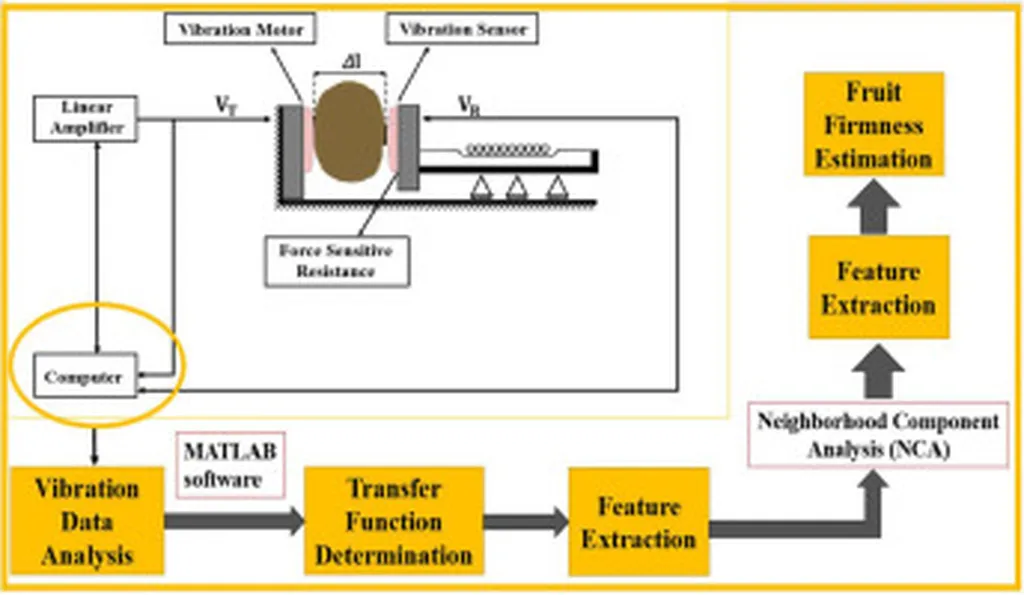

The study, led by Saman Abdanan Mehdizadeh from the Department of Mechanics of Biosystems Engineering at the Agricultural Sciences and Natural Resources University of Khuzestan in Iran, presents a predictive framework that integrates dynamic feature extraction with Neighborhood Component Analysis (NCA) for regression-based feature selection. By subjecting kiwifruit samples to 5-second vibrations, the researchers recorded acceleration and angular velocity in three orthogonal directions, identifying key features such as rise time, overshoot, and damping coefficient that are crucial for predictive modeling.

The resulting model achieved impressive accuracy, with an R² value of 0.981 and a near-zero bias, demonstrating a high fidelity between predicted and actual firmness values. “This level of precision is a game-changer for the agriculture industry,” Mehdizadeh explained. “It allows for real-time monitoring and quality control, ensuring that only the best produce reaches consumers and reducing the amount of waste generated during the supply chain.”

The implications of this research extend beyond kiwifruit. The methodology can be applied to other horticultural crops, supporting precision agriculture and automated quality monitoring systems. “The beauty of this approach is its versatility,” Mehdizadeh added. “By understanding the unique vibration signatures of different fruits, we can tailor our models to suit various crops, making this a truly scalable solution.”

The commercial impacts of this research are substantial. Accurate, non-destructive assessment of fruit firmness can lead to better inventory management, reduced waste, and improved customer satisfaction. It also opens the door for advancements in shelf-life optimization, as understanding the firmness of produce can help predict its longevity and freshness.

As the agriculture sector continues to embrace technology, this research serves as a testament to the power of machine learning and data analysis in driving innovation. By combining dynamic vibration analysis with feature-focused regression, Mehdizadeh and his team have established a highly accurate, efficient, and transferable methodology that could shape the future of post-harvest quality management.

In an era where food waste and sustainability are at the forefront of global concerns, this research offers a promising solution that aligns with the goals of precision agriculture and automated quality monitoring. As the technology evolves, it has the potential to transform the way we approach fruit assessment, ultimately benefiting producers, retailers, and consumers alike.