In an era where technology and agriculture are increasingly intertwined, a groundbreaking study published in *Next Materials* offers a novel solution to two pressing global issues: electromagnetic interference (EMI) and waste management. The research, led by Shivani from the CSIR-Advanced Materials and Processes Research Institute (AMPRI) in Bhopal, India, and the Academy of Scientific and Innovative Research (AcSIR) in Ghaziabad, India, explores the potential of using waste materials to develop effective EMI shielding systems. This innovative approach not only addresses the growing problem of electromagnetic pollution but also provides a sustainable solution for managing industrial, agricultural, and biological waste.

Electromagnetic radiation, a byproduct of our increasingly electrified and automated world, poses significant risks to both living organisms and electronic devices. EMI can cause malfunctions and premature failures in electronic equipment, leading to substantial economic losses. Simultaneously, the accumulation of waste from various sectors, including agriculture, threatens environmental health and sustainability. Shivani’s research bridges these two critical concerns by investigating the use of waste materials in creating EMI shields.

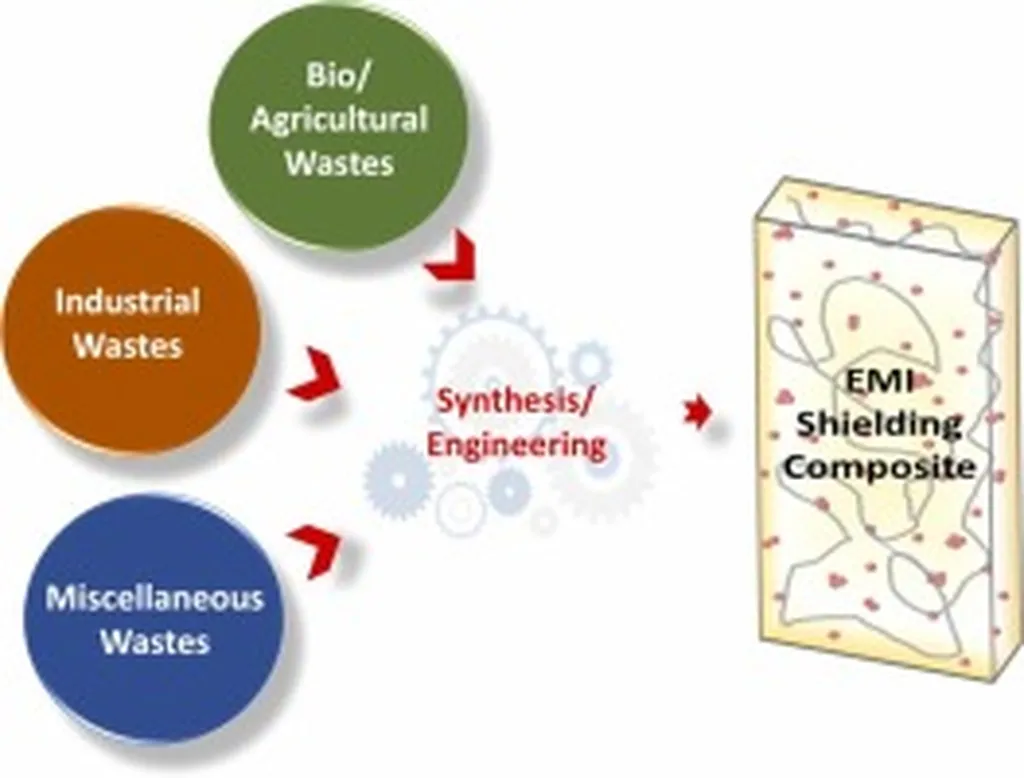

The study provides a comprehensive overview of conventional EMI shielding methods and the challenges associated with their industrial scalability. Traditional shielding materials often rely on metals and synthetic composites, which can be expensive and environmentally harmful. In contrast, the research highlights the potential of incorporating industrial, agricultural, and biological waste into EMI shielding systems. “By utilizing waste materials, we can develop cost-effective and eco-friendly shielding solutions that address both EMI and waste management issues,” Shivani explains.

The article delves into the treatment and fabrication processes of these waste-incorporated shields, emphasizing their effectiveness in mitigating electromagnetic interference. The research also discusses the mechanism of EMI shielding, offering insights into how these innovative materials can be optimized for technological applications. “This study seeks to inspire the scientific community to focus on the utilization of critical wastes and promote their effective use in advanced applications,” Shivani adds.

For the agriculture sector, this research holds significant commercial potential. Agricultural waste, such as crop residues and organic byproducts, can be repurposed to create valuable shielding materials. This not only reduces the environmental impact of agricultural activities but also opens up new revenue streams for farmers and agribusinesses. By integrating waste materials into the production of EMI shields, the agriculture sector can contribute to the development of sustainable and technologically advanced solutions.

The implications of this research extend beyond the agricultural and technological realms. By demonstrating the feasibility of using waste materials for EMI shielding, the study paves the way for future developments in material science and environmental sustainability. As our world becomes increasingly connected and electrified, the demand for effective EMI shielding solutions will continue to grow. This research provides a blueprint for meeting this demand in an environmentally responsible and economically viable manner.

In conclusion, Shivani’s groundbreaking work published in *Next Materials* offers a promising solution to the dual challenges of electromagnetic interference and waste management. By harnessing the potential of waste materials, the agriculture sector and other industries can develop innovative and sustainable shielding systems. This research not only advances our understanding of EMI shielding mechanisms but also highlights the importance of integrating waste materials into technological applications. As we strive towards a more sustainable future, the insights provided by this study will be invaluable in shaping the next generation of environmentally friendly technologies.