In the rapidly evolving landscape of smart agriculture, a groundbreaking development has emerged that promises to revolutionize the way rubber is harvested. Researchers have introduced YOLO-DCS, a high-precision edge detection model designed to swiftly and accurately identify the state of latex collection bowls and latex trails. This innovation, detailed in a recent study published in *Industrial Crops and Products*, could significantly enhance the efficiency and automation of rubber harvesting, offering substantial commercial benefits for the agriculture sector.

The YOLO-DCS model, developed by lead author Jincan Zhu and colleagues at the College of Big Data and Intelligent Engineering, Southwest Forestry University, builds upon the YOLOv10s framework. It incorporates several novel components, including the Dynamic Feature Aggregation (DFA) module, which consolidates dynamic contextual information to improve feature fusion. This allows the model to discern nuanced variations in the condition of collection bowls, such as differences in texture and color.

One of the standout features of YOLO-DCS is its integration of lightweight Depthwise Convolution (DWConv) and SPDConv into both the backbone and head networks. This not only diminishes the model’s parameter size but also preserves high recognition accuracy, resulting in a notable enhancement in inference speed. “The integration of these lightweight components has significantly reduced the model’s computational complexity while maintaining high accuracy,” Zhu explained. “This makes YOLO-DCS particularly suitable for edge computing environments, where computational resources are often limited.”

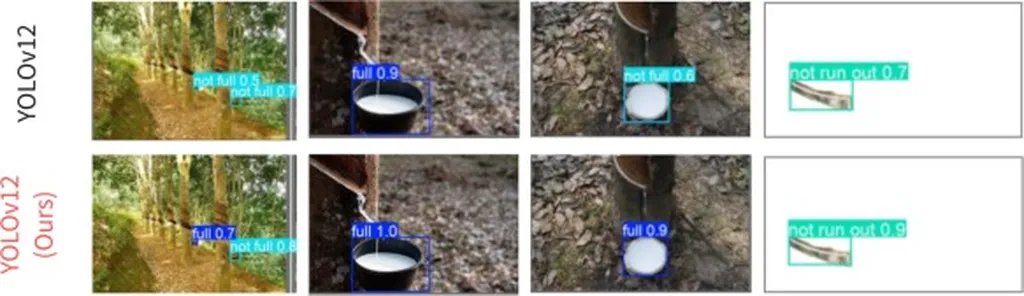

The model’s performance is impressive, achieving a mean Average Precision (mAP) of 82.1% at an intersection over union (IOU) threshold of 0.50 and a mAP of 70.3% across IOU thresholds from 0.50 to 0.95. These figures represent enhancements of 4.7% and 2.2% compared to the original YOLOv10s model, respectively. The recall and F1 Score also saw significant improvements, with recall reaching 78.5% and the F1 Score attaining 84.2%, exceeding the original YOLOv10s by 9.3% and 8.0%, respectively.

Perhaps most notably, YOLO-DCS achieves a GFLOPs (Giga Floating Point Operations per Second) of merely 8.6, representing a 64.9% decrease from the 24.5 GFLOPs of the YOLOv10s model. This remarkable lightweight efficiency underscores the model’s potential for real-world applications in smart agriculture.

The researchers also conducted supplementary comparative experiments on a self-collected infrared dataset to validate the generalization and robustness of the YOLO-DCS model. The results were equally promising, with improvements of 3.3% in mAP0.50 and 3.5% in recall, while significantly reducing GFLOPs by 64.9% compared to the original YOLOv10s model.

The implications of this research are far-reaching. By enhancing the automation and accuracy of rubber harvesting, YOLO-DCS can help farmers increase their yields and reduce labor costs. This could have a profound impact on the commercial viability of rubber plantations, particularly in regions where labor is scarce or expensive.

Moreover, the model’s adaptability and robustness across both visible and infrared scenarios highlight its potential for deployment in a wide range of real-world applications. As the agriculture sector continues to embrace smart technologies, innovations like YOLO-DCS are poised to play a pivotal role in shaping the future of farming.

In the words of Jincan Zhu, “This research not only advances the field of smart agriculture but also demonstrates the potential of edge computing in enhancing the efficiency and accuracy of agricultural practices. We believe that YOLO-DCS will pave the way for more sophisticated and automated harvesting systems in the future.”

As the agriculture sector continues to evolve, the integration of advanced technologies like YOLO-DCS will be crucial in meeting the growing demand for food and other agricultural products. This research, published in *Industrial Crops and Products* and led by Jincan Zhu at the College of Big Data and Intelligent Engineering, Southwest Forestry University, represents a significant step forward in this direction.