In a significant stride towards democratising agricultural technology, researchers from UCLA and North Dakota State University (NDSU) have unveiled AgriCruiser, an open-source field robot designed to make precision spraying and autonomous navigation accessible to strawberry and cereal crop growers. This innovation addresses a critical gap in the market, where existing agricultural robots are often either crop-specific, task-specific, or prohibitively expensive.

The AgriCruiser project is a collaborative effort between the UCLA Structures-Computer Interaction Lab, led by Professor Jonathan Hopkins, and the NDSU Agricultural Engineering research team. PhD researcher Jeffrey Hebel spearheaded the initiative, focusing on creating accessible and replicable ag-tech solutions tailored for small and midsize farms. Unlike commercial platforms such as Thorvald by SAGA Robotics or Prospr by Robotics Plus, which offer modularity but require substantial investments and fixed chassis configurations, AgriCruiser prioritises flexibility and affordability.

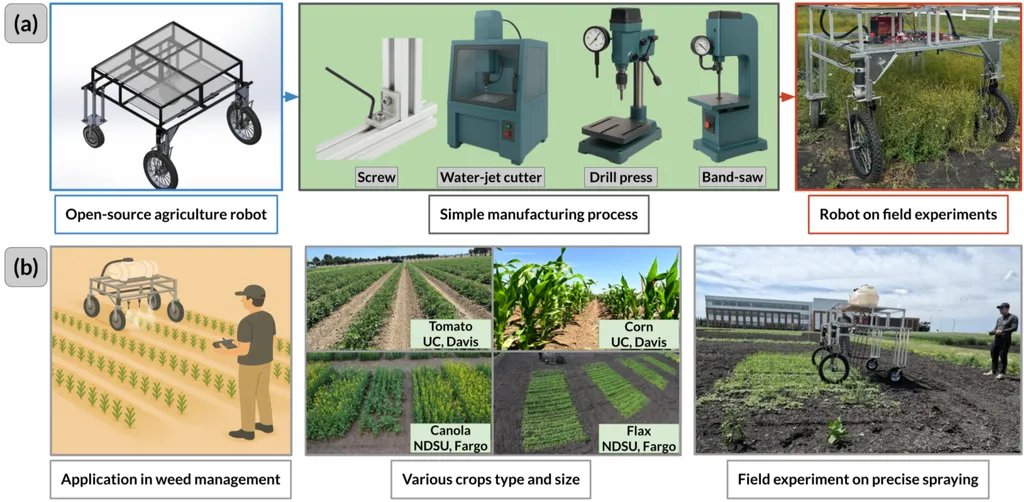

One of the standout features of the AgriCruiser is its modular T-slot chassis, which allows for reconfigurable frame with over-the-row operation. This design enables adjustable track width ranging from 1.42 to 1.57 meters without the need for disassembly. Additionally, it offers high crop clearance of 0.94 meters, allowing the robot to traverse fields even during late growth stages. The robot can perform pivot turns within a radius of 0.71 to 0.76 meters, making it ideal for narrow headlands. This versatility sets AgriCruiser apart from other robots like Odd.Bot Maverick, which is designed for low crops, or Farm-NG’s Amiga, which struggles with taller crops. The AgriCruiser can navigate through flax, canola, and wheat plots without causing crop damage, even at maturity.

The AgriCruiser integrates a 25-gallon herbicide sprayer with pressure-regulated valves and four precision nozzles. During field trials in North Dakota, the robot demonstrated impressive capabilities, spraying 1,003 square meters in just 30 minutes and achieving over 90% weed reduction compared to untreated rows. Notably, it caused six times less crop damage than manual hoeing. Equipped with a compact differential drive and front motorised wheels, the AgriCruiser handles diverse terrain, including wet soil, without stalling—a common issue in many research robots and early commercial models.

Perhaps the most revolutionary aspect of the AgriCruiser is its design philosophy, which emphasises replication over lock-in. The total build cost ranges from $5,000 to $6,000, with 85% of the parts being off-the-shelf and no specialised equipment required. All design files, electronics schematics, and control software are published on GitHub, making it accessible for farmers and developers to replicate and modify. The chassis can be assembled using simple tools like a bandsaw and drill press, further lowering the barrier to entry.

The implications of the AgriCruiser’s open-source design are profound. By providing a cost-effective and flexible alternative, it empowers small and midsize farmers to adopt precision agriculture technologies without the high costs associated with commercial robots. This could lead to increased efficiency, reduced herbicide use, and improved crop yields, ultimately contributing to more sustainable farming practices. The open-source nature of the project also fosters a community-driven approach to innovation, encouraging further developments and adaptations tailored to specific agricultural needs.

As the agricultural sector continues to evolve, the AgriCruiser represents a promising step towards making advanced technologies accessible to a broader range of farmers. Its success could pave the way for more open-source solutions in the ag-tech space, driving innovation and sustainability in agriculture.