In the heart of modern agriculture, where labor costs are climbing and efficiency is paramount, a new breakthrough in machine vision technology is set to revolutionize strawberry picking. Researchers have developed an advanced instance segmentation model that promises to enhance the accuracy and speed of strawberry localization, a critical component for autonomous picking robots. This innovation, detailed in a recent study published in *Information Processing in Agriculture*, could significantly reduce the labor burden in greenhouses and pave the way for more efficient, cost-effective agricultural practices.

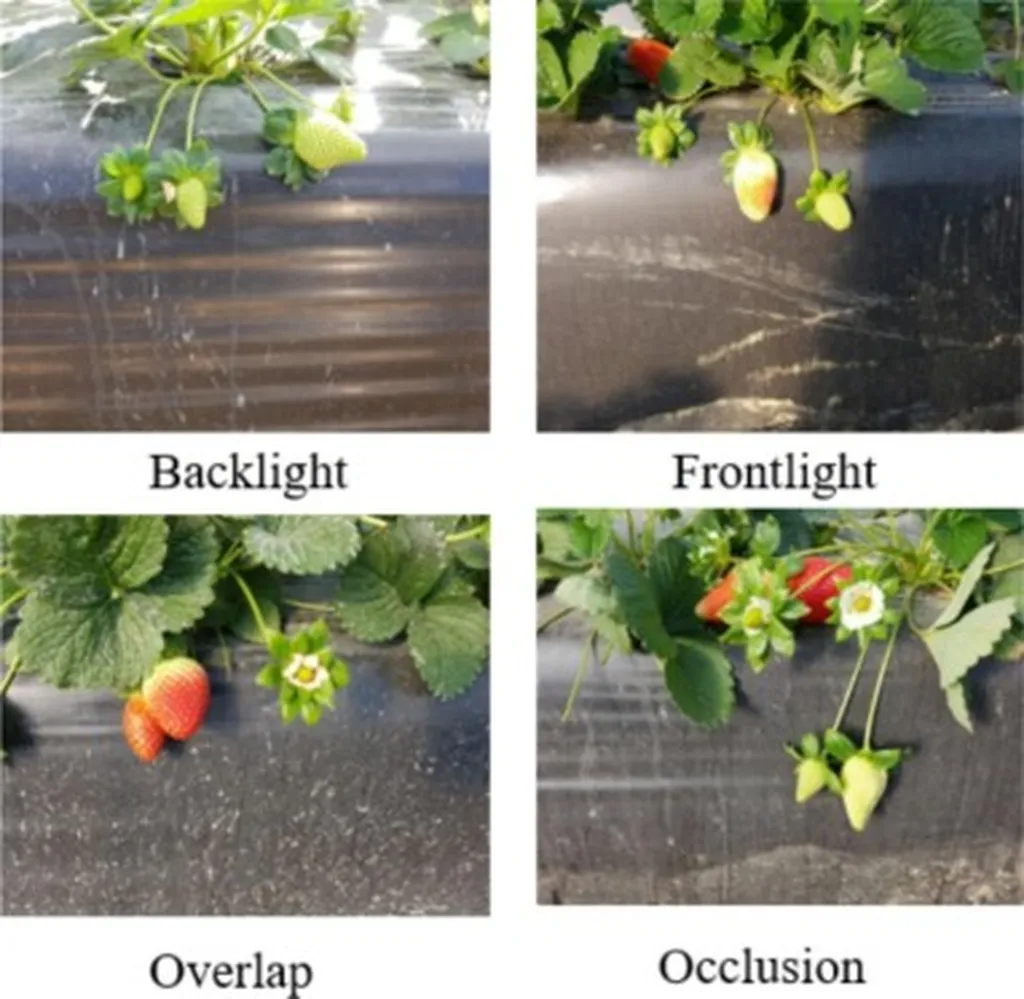

The study, led by Xinhao Zhang from the National Innovation Center for Digital Fishery at China Agricultural University, introduces an improved YOLOv8n model, dubbed YOLOv8n-MCP. This model is specifically optimized for edge computing, making it ideal for real-time robot navigation in greenhouses. The improvements are threefold: first, the model uses MobileNetV3 as its backbone, which enhances feature extraction under varying lighting conditions while reducing the number of parameters and GFLOPs (floating-point operations per second). Second, it incorporates a new Cross-scale Feature Fusion Module (CCFM) as the Neck, improving the detection of strawberries at different distances. Lastly, it employs Partial Convolution (PConv) to enhance the C2f and Head components, further reducing network parameters and GFLOPs while boosting frames per second (FPS).

The results are impressive. Compared to the original YOLOv8n model, YOLOv8n-MCP reduces parameters by 69%, GFLOPs by 56%, and increases FPS by 42%. When tested on Nvidia Jetson Xavier NX, the model achieved 49.5 FPS, significantly outperforming the original YOLOv8n’s 37.6 FPS. This performance is crucial for real-time strawberry instance segmentation during robot navigation.

“Our goal was to create a model that could efficiently and accurately detect strawberries in various lighting conditions and at different distances,” said Xinhao Zhang. “The YOLOv8n-MCP model not only meets these requirements but also operates seamlessly on edge devices, making it practical for real-world applications.”

The commercial implications of this research are substantial. As labor costs continue to rise, the adoption of autonomous picking robots could become a game-changer for the agriculture sector. These robots, equipped with advanced instance segmentation models like YOLOv8n-MCP, can work tirelessly and accurately, reducing the need for human labor and increasing productivity. This could lead to lower operational costs and higher yields, benefiting both farmers and consumers.

Moreover, the model’s efficiency on edge devices means that it can be easily integrated into existing agricultural robots without the need for extensive hardware upgrades. This makes the technology more accessible and cost-effective for farmers looking to modernize their operations.

The research also opens up new avenues for future developments in the field. As Zhang and his team continue to refine their model, the potential applications could extend beyond strawberry picking to other crops and agricultural tasks. The focus on edge computing and lightweight networks also aligns with the broader trend towards more efficient and sustainable agricultural technologies.

In conclusion, the YOLOv8n-MCP model represents a significant step forward in the quest for more efficient and accurate strawberry picking robots. Its impressive performance metrics and practical applications make it a promising tool for the future of agriculture. As the technology continues to evolve, it could play a pivotal role in shaping the next generation of agricultural robots, ultimately transforming the way we grow and harvest our food.