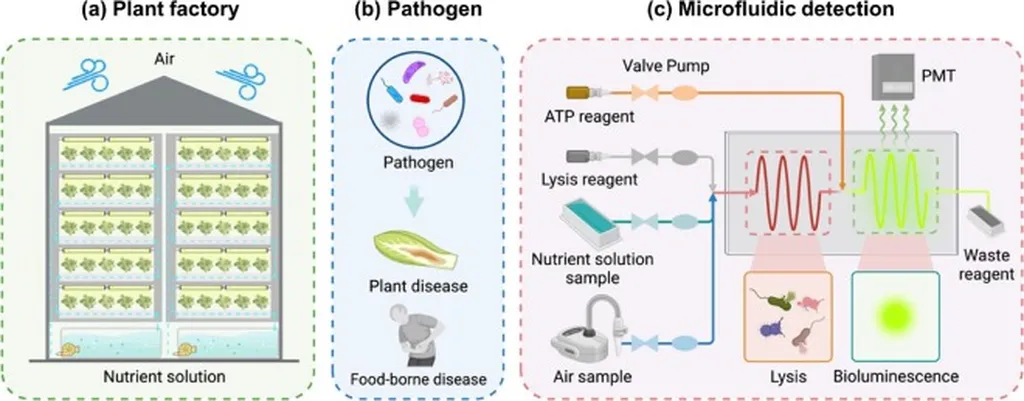

In the high-stakes world of plant factories, where precision and hygiene are paramount, a new technological breakthrough promises to revolutionize microbial monitoring. Researchers have developed an integrated microfluidic biosensor that could significantly enhance the efficiency and reliability of detecting microbial contamination in both air and nutrient solutions. This innovation, published in *Information Processing in Agriculture*, addresses a critical gap in the industry, offering a rapid, cost-effective, and user-friendly solution.

Microbial contamination in plant factories is a persistent challenge, often leading to economic losses and potential health risks. Traditional detection methods are notoriously slow, expensive, and require skilled technicians, making them impractical for routine monitoring. The new microfluidic biosensor, developed by a team led by Weizhong Yu at the Key Laboratory of Agricultural Engineering in Structure and Environment of the Ministry of Agriculture and Rural Affairs, China Agricultural University, aims to change that.

The biosensor combines ATP bioluminescence with microfluidic technology to quantify microbial levels. “This integration allows for a detection process that is completed within just three minutes,” Yu explained. The device consumes minimal amounts of ATP reaction solution and lysate, making it both efficient and economical. With a sensitivity of up to 6.4 × 10³ CFU mL⁻¹ and a detection range covering four orders of magnitude, the biosensor matches the accuracy of traditional culture counting methods while significantly reducing detection times.

The implications for the agriculture sector are substantial. Plant factories, which rely on controlled environments to optimize plant growth, stand to benefit immensely from this technology. “The ability to monitor microbial levels in real-time can prevent contamination before it becomes a problem, thereby protecting both crop yields and consumer health,” Yu noted. This proactive approach could translate into substantial cost savings for farmers and producers, as well as enhanced product quality and safety.

Beyond immediate applications, this research opens the door to further innovations in agricultural technology. The microfluidic biosensor’s success could inspire the development of similar devices for other aspects of plant and soil health monitoring. As the agriculture industry continues to embrace technology, tools like this could become standard in modern farming practices, ensuring higher productivity and sustainability.

The commercial impact of this technology is already being recognized. The biosensor’s ability to provide rapid, accurate, and cost-effective microbial monitoring positions it as a valuable asset for plant factories worldwide. As the technology becomes more widely adopted, it could set a new standard for microbial detection in agriculture, driving the industry towards greater efficiency and safety.

In the rapidly evolving field of agritech, this breakthrough represents a significant step forward. By addressing a longstanding challenge in plant factories, the microfluidic biosensor not only enhances current practices but also paves the way for future innovations. As researchers continue to refine and expand its applications, the agriculture sector can look forward to a future where contamination is detected and managed with unprecedented speed and precision.