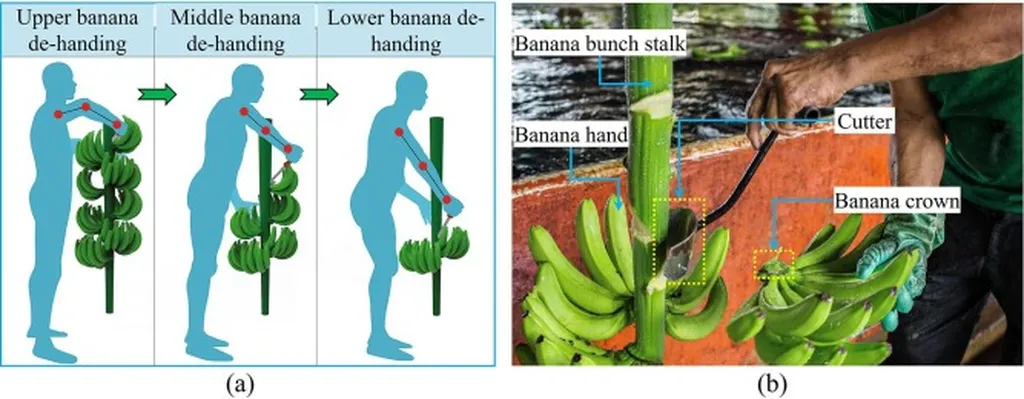

In the heart of China’s agricultural innovation, a breakthrough in robotic harvesting technology is poised to revolutionize the banana industry, offering a glimpse into the future of smart agriculture. Researchers, led by Bowei Xie from the College of Mechanical and Electrical Engineering at Hunan Agricultural University, have developed an adaptive flexible end-effector designed specifically for banana bunch harvesting. This innovation addresses a longstanding challenge in the agriculture sector: the labor-intensive and often damaging process of manual banana harvesting.

The study, published in the journal *Agronomy*, introduces a systematic approach to designing and optimizing soft robotic grippers that mimic the delicate touch required to handle bananas without causing damage. By integrating response surface methodology (RSM) with multi-objective genetic algorithm (MOGA) optimization, the team quantified the relationships between finger geometry parameters and key performance metrics such as contact area, contact stress, and radial stiffness. The result is a gripper that not only improves handling performance but also ensures harvesting stability during dynamic loading.

“Our optimized flexible fingers effectively distribute contact pressure, minimizing fruit damage and enhancing grasping reliability,” Xie explained. “This is a significant step forward in automated harvesting technology, as it addresses the critical need for gentle yet secure handling of fragile produce.”

The implications for the agriculture sector are substantial. Banana harvesting, traditionally reliant on manual labor, is both labor-intensive and prone to fruit damage due to insufficient control of contact forces. The new end-effector design promises to reduce these issues dramatically. Experimental and simulation results show that the optimized fingers increase contact area by 13–28%, reduce contact stress by 45–56%, and enhance radial stiffness by 193%. Perhaps most notably, the maximum shear stress on the fruit stalk decreases by 90%, ensuring that bananas are harvested with minimal damage.

This innovation is not just about improving the efficiency of banana harvesting; it’s about setting a new standard for soft robotic handling of fragile and irregular agricultural products. The design framework proposed by Xie and his team enables passive adaptation to fruit morphology without the need for complex sensors, making it a versatile solution for various agricultural applications.

As the agriculture sector continues to embrace automation and smart technologies, this research paves the way for more efficient and sustainable harvesting practices. The commercial impact could be profound, offering farmers a tool that not only reduces labor costs but also enhances the quality and yield of their crops. By bridging the gap between bio-inspired gripper design and practical agricultural application, this work provides both theoretical insights and engineering guidance for the development of automated, low-damage fruit harvesting systems.

In an era where precision and sustainability are paramount, this breakthrough in soft robotic technology is a testament to the power of innovation in agriculture. As the industry continues to evolve, the insights gained from this research will undoubtedly shape the future of harvesting technologies, offering a glimpse into a world where automation and gentleness coexist for the benefit of both farmers and consumers.