In the ever-evolving landscape of precision agriculture, a groundbreaking study published in *IEEE Access* is set to revolutionize how farmers and agribusinesses estimate the weight of pomegranates without causing any damage to the fruit. The research, led by K. R. Bhavya from the Department of Computer Science and Engineering at GITAM (Deemed to be University) in Bengaluru, introduces FeaFusion-PomoNet, a novel feature fusion-based regression framework designed to predict the weight of pomegranates using images captured from multiple orientations.

The significance of non-destructive weight estimation cannot be overstated. Accurate weight prediction is crucial for yield forecasting, grading, and optimizing logistics, all of which are vital for the commercial success of agricultural enterprises. Traditional methods often involve destructive testing, which not only wastes produce but also fails to provide real-time data. FeaFusion-PomoNet addresses these challenges head-on by leveraging advanced image processing and machine learning techniques.

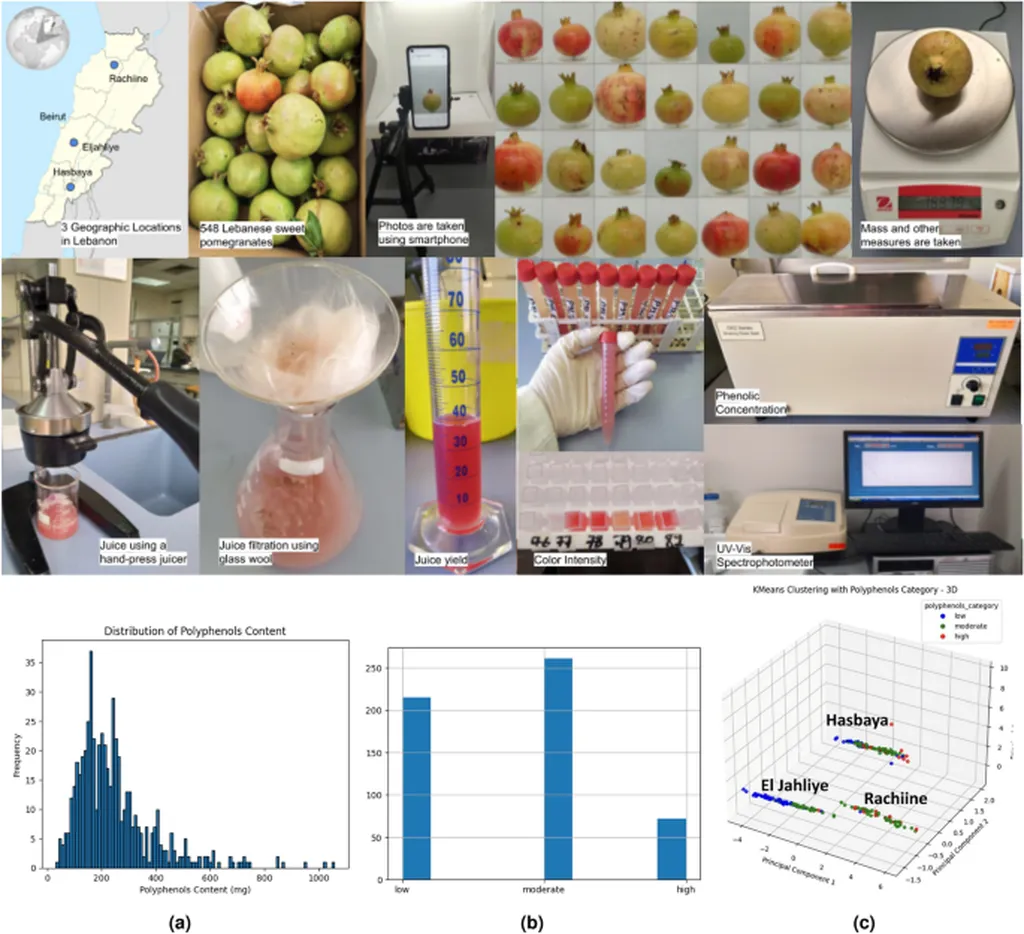

The framework extracts a variety of handcrafted features, including texture, shape, geometric attributes, and pixel density, from images of pomegranates. These features are then optimized using the Boruta feature selection algorithm, ensuring that only the most relevant data is used for prediction. Multiple regression models were evaluated, with Multiple Linear Regression (MLR) emerging as the top performer. The model achieved impressive R2 scores of 0.97 and 0.92 on 80-20 and 70-30 train-test splits, respectively, indicating a high degree of accuracy.

Validation through Mean Absolute Error (MAE) and Root Mean Squared Error (RMSE) produced average relative error rates of 7.6% and 8.3%, further confirming the robustness of the model. A Pearson correlation coefficient of 0.99 underscores the strong predictive power of FeaFusion-PomoNet. “This level of accuracy is a game-changer for the agriculture sector,” says Bhavya. “It allows for real-time, non-destructive assessment of fruit weight, which can significantly enhance operational efficiency and reduce waste.”

One of the standout features of FeaFusion-PomoNet is its ability to support orientation-independent image acquisition. This adaptability is particularly beneficial for irregularly shaped fruits like pomegranates, making the model versatile and practical for real-world applications. “Our goal was to create a system that could be easily integrated into existing agricultural workflows,” explains Bhavya. “By eliminating the need for precise image orientation, we’ve made the process more accessible and user-friendly.”

The commercial implications of this research are vast. For farmers, accurate weight estimation can lead to better yield management and improved grading, ultimately increasing profitability. For agribusinesses, the ability to optimize logistics and reduce waste can result in significant cost savings. The potential for automation in post-harvest systems is also a compelling prospect, as it can streamline operations and enhance overall efficiency.

Looking ahead, the research team plans to scale the dataset and incorporate field-captured images to improve the model’s robustness under real-world conditions. “We are committed to refining our approach to ensure it meets the diverse needs of the agriculture sector,” says Bhavya. “Our ultimate aim is to contribute to the development of automated, cost-effective post-harvest systems that can benefit farmers and agribusinesses alike.”

As the agriculture sector continues to embrace technological advancements, innovations like FeaFusion-PomoNet are poised to play a pivotal role in shaping the future of smart agriculture. By providing accurate, non-destructive weight estimation, this research not only enhances operational efficiency but also paves the way for more sustainable and profitable agricultural practices.