In the quest for sustainable solutions to nitrate contamination, a recent study published in *Scientific Reports* offers a promising breakthrough. Researchers, led by Laleh Divband Hafshejani from the Department of Environmental Engineering at Shahid Chamran University of Ahvaz, have uncovered a novel approach to optimizing nitrate removal using rapeseed-derived biochar. The study not only sheds light on the critical role of chemical modification pathways but also integrates machine learning to predict and enhance adsorption efficiency.

Nitrate contamination, stemming from agricultural runoff and industrial activities, poses significant threats to both human health and aquatic ecosystems. Traditional remediation methods often fall short in terms of sustainability and cost-effectiveness. Enter biochar—a carbon-rich material produced through the pyrolysis of organic matter. When chemically modified, biochar can act as a highly effective adsorbent, but the impact of modification sequences and operational conditions on its performance has remained largely unexplored until now.

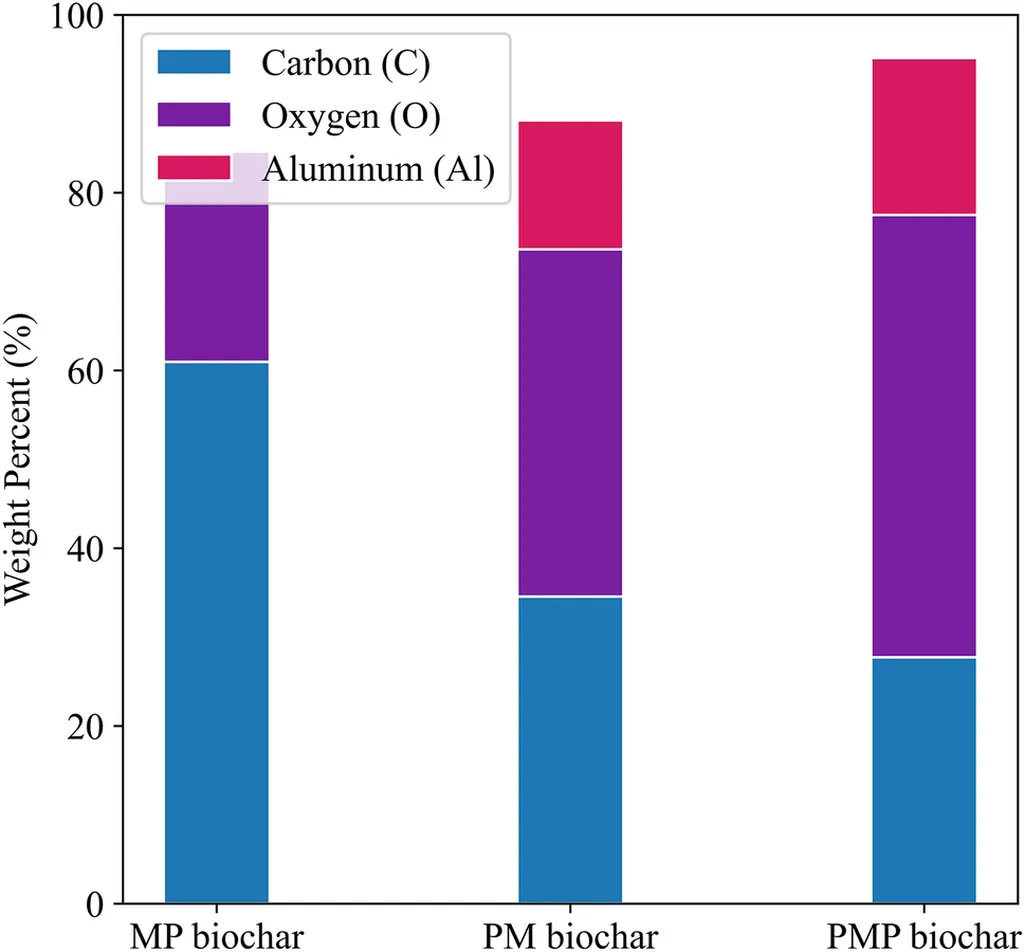

The research team investigated three distinct pathways for modifying rapeseed biochar with aluminum: pre-pyrolysis (MP), post-pyrolysis (PM), and post-pyrolysis with re-pyrolysis (PMP). Through comprehensive characterization techniques, including BET, SEM, EDS, XRD, and FTIR, they found that PM biochar exhibited the highest surface area, uniform mesoporous structure, stable aluminum content, and abundant oxygen-containing functional groups. These properties translated into superior nitrate adsorption capabilities.

“Our findings demonstrate that the sequence of chemical modification plays a pivotal role in tailoring the structure and functionality of biochar,” said Divband Hafshejani. “By optimizing this process, we can significantly enhance its adsorption efficiency, making it a more viable solution for nitrate removal.”

Batch experiments revealed that adsorption efficiency is influenced by several operational parameters, including initial nitrate concentration, contact time, adsorbent dose, solution pH, and the presence of competing anions. Notably, CO₃2⁻ and SO₄2⁻ had the strongest inhibitory effects on adsorption. Regeneration tests further confirmed the reusability of PM biochar, retaining approximately 76% of its initial adsorption capacity after five adsorption–desorption cycles.

To predict nitrate removal more accurately, the researchers applied nonlinear machine learning models, including Random Forest (RF), Support Vector Regression (SVR), and Linear Regression (LR). The Random Forest model achieved the highest predictive accuracy, with an R² value of 0.892 and an RMSE of 0.078, showcasing its robustness and generalization capabilities.

“This integration of AI-based modeling provides a data-driven framework for designing high-performance biochars,” explained Divband Hafshejani. “It allows us to optimize the modification process and predict outcomes more accurately, ultimately leading to more effective and sustainable water treatment solutions.”

The implications of this research extend beyond environmental remediation. For the agriculture sector, which is a significant contributor to nitrate pollution, this study offers a sustainable and cost-effective method for managing nitrate runoff. By adopting chemically modified biochar, farmers can not only mitigate environmental impact but also potentially enhance soil health and crop yields.

As the world grapples with the challenges of water pollution and sustainable agriculture, this research paves the way for innovative solutions that bridge the gap between environmental science and technology. By leveraging the power of machine learning and advanced materials science, we can look forward to a future where nitrate contamination is effectively managed, and our water resources are safeguarded for generations to come.