In the world of tea production, precision and quality control are paramount. A recent study published in *Shipin Kexue* has introduced a groundbreaking method for detecting the moisture content of withered leaves used in black tea production, leveraging micro-near infrared spectroscopy (NIR). This innovation, led by LI Haoxun and colleagues from the School of Electrical Engineering and Automation at Tianjin University of Technology and the Tea Research Institute of the Shandong Academy of Agricultural Sciences, promises to revolutionize the tea industry by enhancing efficiency and consistency in production processes.

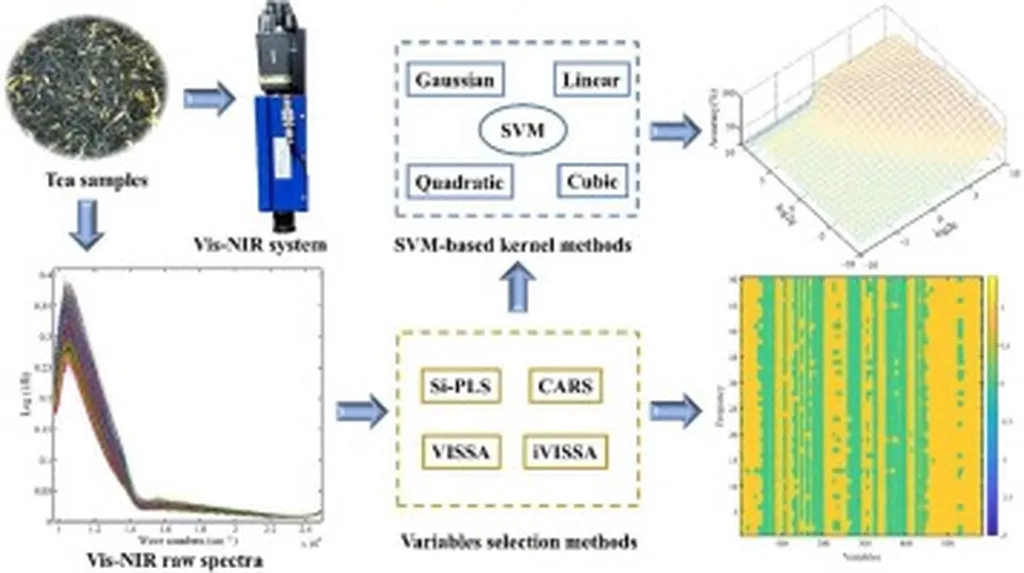

The research team developed an NIR spectrometer to collect diffuse reflectance spectra of withered leaf samples, correlating these spectral data with moisture content measurements taken at various stages of the withering process. By employing advanced data preprocessing techniques, variable screening methods, and principal component analysis (PCA), the researchers optimized and reduced the dimensionality of the spectral data. This allowed them to establish both a discriminant model for the withering degree and a prediction model for the moisture content of Yimeng black tea.

The results were impressive. The random forest (RF) discriminant model achieved an accuracy rate of 99.4% on the test set, demonstrating exceptional classification performance. Additionally, the model developed using bootstrapping soft shrinkage combined with support vector regression (BOSS-SVR) showed robust prediction capabilities, with a correlation coefficient of prediction (rp) of 0.984 and a relative percent deviation (RPD) of 4.485. These metrics indicate a high level of accuracy and reliability in predicting moisture content, which is crucial for maintaining the quality of black tea.

“This research provides a theoretical basis and data support for the standardized and digital production of Yimeng black tea,” said LI Haoxun, the lead author of the study. The implications of this work extend beyond the tea industry, offering a blueprint for other agricultural sectors looking to integrate advanced spectroscopic techniques into their quality control processes.

The commercial impact of this research is significant. By enabling non-destructive and real-time monitoring of moisture content, tea producers can ensure consistent quality and reduce waste, ultimately leading to higher profitability. “The ability to accurately predict moisture content without damaging the leaves is a game-changer,” added LI Haoxun. “It allows us to optimize the withering process, ensuring that the tea leaves reach the ideal moisture level for the best possible final product.”

The study’s findings were published in *Shipin Kexue*, with contributions from LI Haoxun, YU Xiao, DONG Chunwang, CHEN Zhiwei, GUO Mengqi, and PENG Weijie, affiliated with the School of Electrical Engineering and Automation at Tianjin University of Technology and the Tea Research Institute of the Shandong Academy of Agricultural Sciences.

As the agricultural sector continues to embrace digital transformation, this research highlights the potential of advanced spectroscopic techniques to drive innovation and efficiency. The integration of NIR spectroscopy into tea production processes not only enhances quality control but also paves the way for similar applications in other crops, ultimately contributing to a more sustainable and productive agricultural future.