In the quest for sustainable solutions to agricultural and food industry challenges, a groundbreaking study has emerged from the Department of Chemical Engineering at Tribhuwana Tunggadewi University in Indonesia. Led by Sinar Perbawani Abrina Anggraini, the research focuses on optimizing the production of liquid smoke from coconut shell waste using slow pyrolysis in a fixed-bed reactor. The findings, published in *Sustainable Chemistry for Climate Action*, offer promising insights into reducing environmental impact while enhancing commercial viability in the agriculture sector.

Coconut shell waste, a common byproduct of the coconut industry, poses significant environmental and health risks. However, this waste can be transformed into valuable bio-oil through pyrolysis, a process that converts organic materials into useful products using heat in the absence of oxygen. The study aimed to identify the chemical components of pyrolytic coconut shell oil and optimize the production process using Response Surface Methodology (RSM) with Face-Centered Central Composite Design (FCCD).

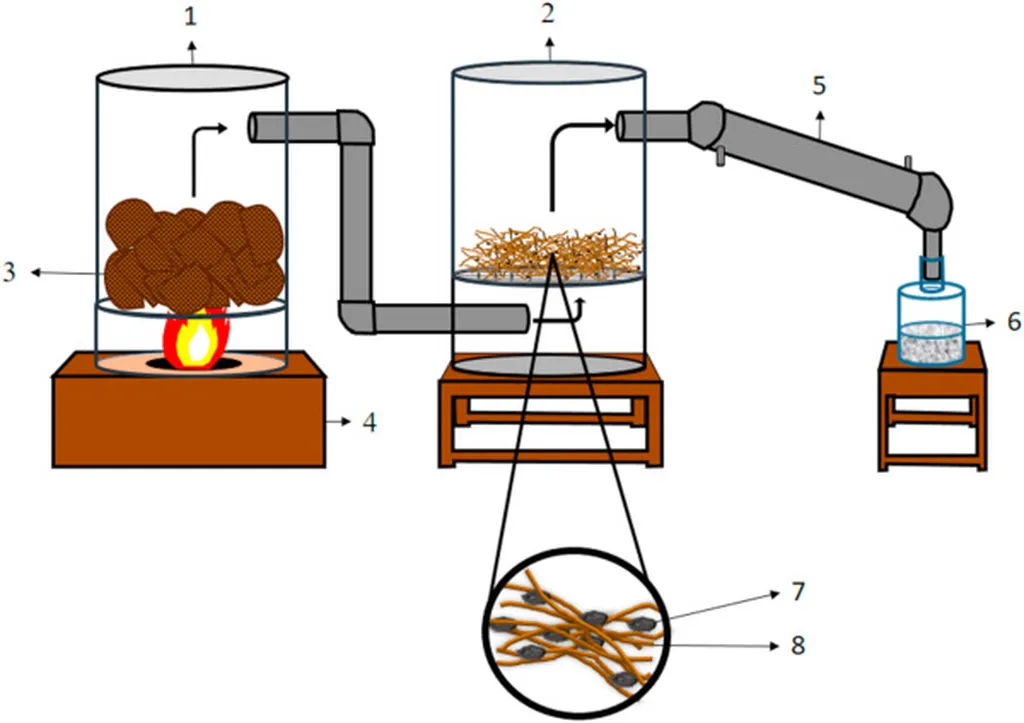

The research team conducted experiments in an electrically heated fixed-bed reactor, varying key parameters such as time (5–30 minutes), temperature (210–410℃), and coconut shell size (1–3 mm). Their goal was to achieve the optimal yield of liquid smoke. The results revealed that the yield decreased with smaller material sizes but increased with higher temperatures and longer heating times. The optimal conditions were found to be a temperature of 400℃, a material size of 2 mm, and a heating time of 30 minutes, yielding 46% liquid smoke.

“This study not only demonstrates the feasibility of converting coconut shell waste into a valuable product but also highlights the importance of optimizing process parameters to maximize yield and efficiency,” said Anggraini. The research identified seven key chemical components in the liquid smoke, including phenol, dimethoxy phenol, guaiacol, hydroxyanisole, and methoxyphenol, which contribute to its antimicrobial properties and potential applications in the food and agriculture industries.

The commercial implications of this research are substantial. Liquid smoke is widely used as a natural flavor enhancer and preservative in the food industry, and its production from coconut shell waste offers a sustainable alternative to traditional methods. By reducing reliance on non-renewable resources and minimizing waste, this innovation aligns with global efforts to promote circular economies and reduce carbon footprints.

Moreover, the successful application of FCCD-RSM in predicting the optimal conditions for liquid smoke production sets a precedent for future research in the field. This methodology can be adapted to other types of organic waste, opening new avenues for sustainable resource utilization. As the agriculture sector continues to seek eco-friendly solutions, the insights from this study could pave the way for innovative approaches to waste management and value addition.

In summary, the research led by Anggraini and her team at Tribhuwana Tunggadewi University represents a significant step forward in the quest for sustainable agriculture and food production. By transforming coconut shell waste into a valuable commodity, this study not only addresses environmental concerns but also offers economic benefits for the agriculture sector. As the world continues to grapple with the challenges of climate change and resource depletion, such innovations are crucial in shaping a more sustainable future.