In the ever-evolving landscape of agricultural automation, a groundbreaking study published in *工程科学学报* is set to redefine the capabilities of harvesting robotic manipulators. Led by Kaifeng Qiao from the School of Electrical and Electronic Engineering at Shandong University of Technology, the research introduces an innovative event-triggered intermittent trajectory-tracking control strategy that promises to strike a delicate balance between performance and cost in agricultural robotics.

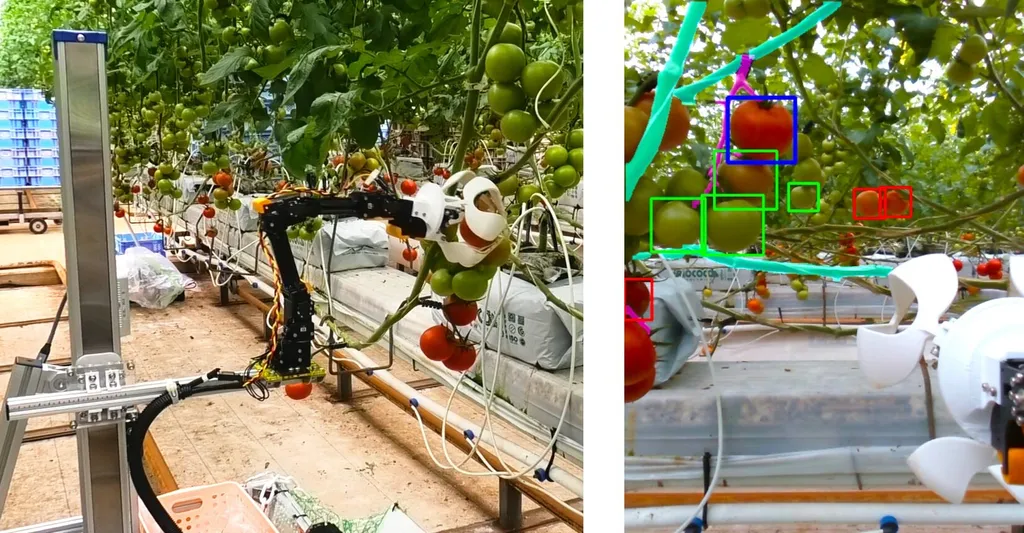

Robotic manipulators have become indispensable in modern agriculture, particularly in orchards and greenhouses, where they navigate unstructured environments to perform precise harvesting tasks. However, these environments present unique challenges, including external disturbances and unknown dynamics, which demand robust control strategies. Traditional continuous control methods, while effective, often require high-frequency monitoring and real-time computation, leading to significant control costs.

Qiao’s research addresses these challenges head-on by proposing a novel control strategy that operates intermittently, switching between active control and dormant phases. This approach not only reduces the computational burden but also extends the operational endurance of the robotic manipulators. “Our strategy effectively reduces the computational burden and communication bandwidth requirements while significantly extending operational endurance,” Qiao explains. “This is crucial for reducing the overall control cost in agricultural applications.”

The study employs a dual-joint harvesting robotic manipulator dynamic model, developed using Lagrangian mechanics principles. This model accounts for various factors, including inertial properties, Coriolis effects, gravitational loading, and disturbance inputs. To enhance system stability and robustness, the researchers implemented a radial basis function neural-network architecture to estimate unknown nonlinear dynamics and external disturbances.

One of the key innovations in this research is the use of the supremum-infimum technique to partition the operational period into actively controlled intervals and dormant rest phases. This partitioning establishes a precisely quantified relationship between control and rest intervals, allowing the controller to execute event-triggered actions during control intervals while suspending all control computations and transmissions during rest intervals.

The stability analysis, conducted using Lyapunov theory, confirms that the proposed control strategy ensures both trajectory-tracking and neural-network estimation errors converge to a bounded region. This achievement is significant as it enables the desired tracking objectives to be met within specified error margins. Moreover, the study establishes the uniform boundedness of all closed-loop signals, confirming the absence of Zeno behavior—a critical property that ensures no infinite triggering occurs during any finite operational period.

The practical implications of this research are profound for the agriculture sector. By reducing the controller update frequency by 68.31% compared to continuous control and improving the overall root mean square error (RMSE) for Joints 1 and 2 by 22.18% and 33.63% respectively, compared to conventional PID control, the proposed strategy offers a compelling solution for enhancing the efficiency and cost-effectiveness of agricultural robotics.

As the agriculture industry continues to embrace automation, the demand for advanced control strategies that can operate efficiently in harsh environments will only grow. Qiao’s research not only meets this demand but also sets a new benchmark for future developments in the field. By optimizing the balance between tracking accuracy, computational cost, and communication cost, this study paves the way for more sophisticated and efficient harvesting robotic manipulators, ultimately benefiting farmers and the agriculture sector as a whole.

The research, published in *工程科学学报*, represents a significant advancement in the field of agricultural automation, with the potential to revolutionize the way robotic manipulators are deployed in orchards and greenhouses. As the agriculture sector continues to evolve, the insights and innovations presented in this study will undoubtedly play a pivotal role in shaping the future of agricultural robotics.