In the ever-evolving landscape of agricultural technology, a groundbreaking study has emerged that could redefine the efficiency and sustainability of plastic extrusion processes, a critical component in the production of various agricultural equipment and materials. Published in the esteemed journal ‘IEEE Access,’ the research, led by Jose Alonso Dena-Aguilar of EPM-SECIHTI, Centro de Investigaciones en Óptica A. C., Aguascalientes, Mexico, introduces a redesigned hybrid (electric-solar) plastic extruder machine that promises to revolutionize the industry.

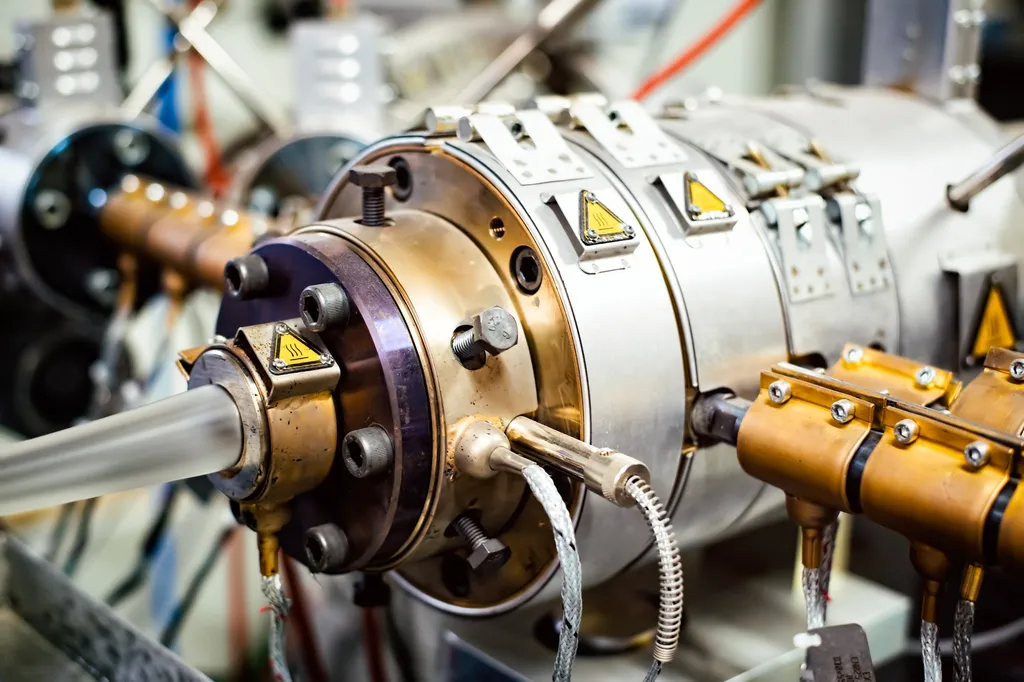

The study focuses on the redesign and programmable logic controller (PLC)-based automation of a unique hybrid plastic extruder, enabling reliable operation above 300°C. This innovation is a game-changer for the agricultural sector, where precision and efficiency are paramount. “The key to our success lies in the individual control of six resistance band heaters via a programmable logic controller and enhanced solar absorption on the barrel,” explains Dena-Aguilar. This level of control ensures that the extruder can handle a wide range of thermoplastics, including LDPE, PS, PET, and PP, which are commonly used in agricultural applications.

The experimental evaluation of the reengineered system under electric, solar, and hybrid operating modes revealed impressive results. Solar-only heating reached 138°C in 150 minutes, demonstrating its effectiveness as a preheating supplement. The hybrid mode achieved a maximum barrel temperature of 362°C, reducing heating times and electrical energy consumption significantly. “Compared to electric-only operation, the hybrid mode reduced heating times to 200, 260, and 300°C by 16.7%, 27.5%, and 29.0%, respectively, and decreased electrical energy consumption by up to 29%,” Dena-Aguilar noted. This energy efficiency is crucial for the agricultural sector, where cost-effective and sustainable solutions are in high demand.

The study also employed finite element analysis (FEA) to verify the thermomechanical integrity of the barrel and screw, ensuring the system’s reliability and durability. Preliminary loaded extrusion tests further confirmed the hybrid mode’s superiority, reducing electrical energy consumption by 25.64% relative to electric-only mode while processing 2 kg of LDPE.

The implications of this research for the agricultural sector are profound. The integration of concentrated solar energy and advanced PLC control not only improves energy efficiency but also enhances thermal flexibility and overall system performance. This innovation supports the processing of common thermoplastics used in agricultural equipment, packaging, and other applications, advancing sustainable extrusion through renewable energy integration.

As the agricultural industry continues to seek sustainable and cost-effective solutions, the hybrid extruder machine offers a promising avenue for future developments. The synergy between concentrated solar energy and advanced PLC control demonstrated in this study could pave the way for more efficient and environmentally friendly extrusion processes, ultimately benefiting the entire agricultural supply chain. With the research published in ‘IEEE Access’ and led by Jose Alonso Dena-Aguilar of EPM-SECIHTI, Centro de Investigaciones en Óptica A. C., Aguascalientes, Mexico, the agricultural sector can look forward to a future where innovation and sustainability go hand in hand.