In the rapidly evolving world of controlled-environment agriculture, the concept of digital twins (DTs) is gaining traction as a powerful tool for optimizing microclimate conditions and energy efficiency. A recent study published in *AgriEngineering* introduces a novel approach to maintaining the accuracy and efficiency of these digital twins over time, addressing a critical challenge in the industry.

The research, led by Ivan S. Nekrasov from the Department of Technological Machines and Equipment of Oil and Gas Complex at Siberian Federal University, focuses on developing a self-adaptive digital twin for phytotron chambers. These chambers are essential for vertical farming, where precise control of temperature and humidity is crucial for crop growth and energy management.

The study combines a Model-based Adaptive Prediction, Estimation, and Control Knowledge (MAPE-K) loop with an evolutionary heuristic, specifically a genetic algorithm (GA), to calibrate the digital twin parameters continuously. This approach allows the system to adapt to long-term drift and seasonal variability, ensuring accurate modeling of the microclimate.

“Our method not only calibrates the digital twin but also optimizes the heater control settings, leading to significant energy savings,” explains Nekrasov. The research demonstrates that by using six monitoring intervals from May to June 2025, the calibrated digital twin can reproduce temperature and humidity with high fidelity, achieving average cross-validated deviations of just 0.27 °C and 7.1% relative humidity.

One of the most compelling aspects of this study is its potential impact on the agriculture sector. The optimized controller settings resulted in cumulative energy savings of 186.54 kWh, or 3.24% over the six intervals, with per-interval savings ranging from 0.37% to 5.94%. These savings are not just theoretical; they represent a practical pathway for reducing operational costs in vertical farms, making them more economically viable and environmentally sustainable.

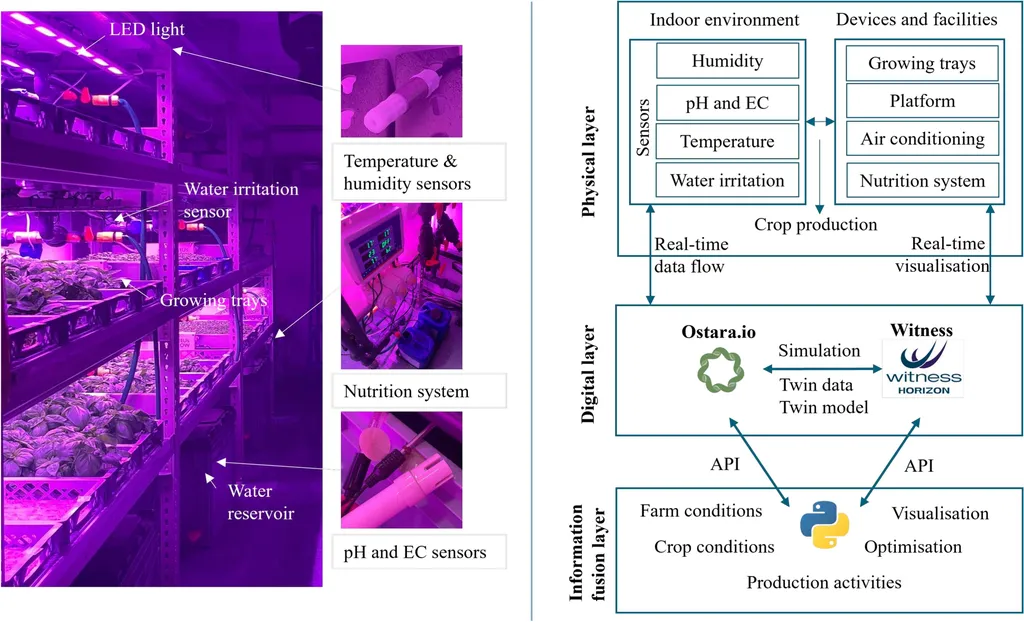

The integration of IoT monitoring with the digital twin allows for real-time adjustments, ensuring that the microclimate remains optimal for plant growth. This self-adaptive calibration method could revolutionize how vertical farms operate, providing a robust solution for year-round production.

As the agriculture industry continues to embrace technology, the findings from this study offer a glimpse into the future of controlled-environment agriculture. By coupling GA-based digital twin calibration with model-in-the-loop controller optimization, farmers and agritech companies can achieve consistent energy savings while maintaining the quality of the microclimate.

“This research provides a practical pathway for the robust, year-round operation of vertical farms,” Nekrasov emphasizes. The implications are vast, potentially reshaping the way we approach vertical farming and controlled-environment agriculture.

The study, published in *AgriEngineering* and led by Ivan S. Nekrasov from the Department of Technological Machines and Equipment of Oil and Gas Complex at Siberian Federal University, marks a significant step forward in the field. As the industry continues to evolve, the integration of advanced algorithms and adaptive schemes will be crucial in driving efficiency and sustainability in agriculture.