In the ever-evolving landscape of agricultural technology, a groundbreaking study has emerged that promises to revolutionize tobacco production. Researchers have developed a digital twin-driven deep learning framework designed to enhance the quality inspection process during tobacco transplanting. This innovation, published in *Frontiers in Plant Science*, addresses longstanding challenges in the industry, offering a more efficient and accurate approach to crop management.

Traditionally, tobacco transplanting quality inspection has relied heavily on manual methods, which are not only time-consuming and labor-intensive but also prone to inconsistencies. The new framework, developed by Qiuyang Zhao from the School of Technology at Beijing Forestry University and colleagues, introduces a sophisticated system that integrates deep learning and digital twin technology to streamline the inspection process.

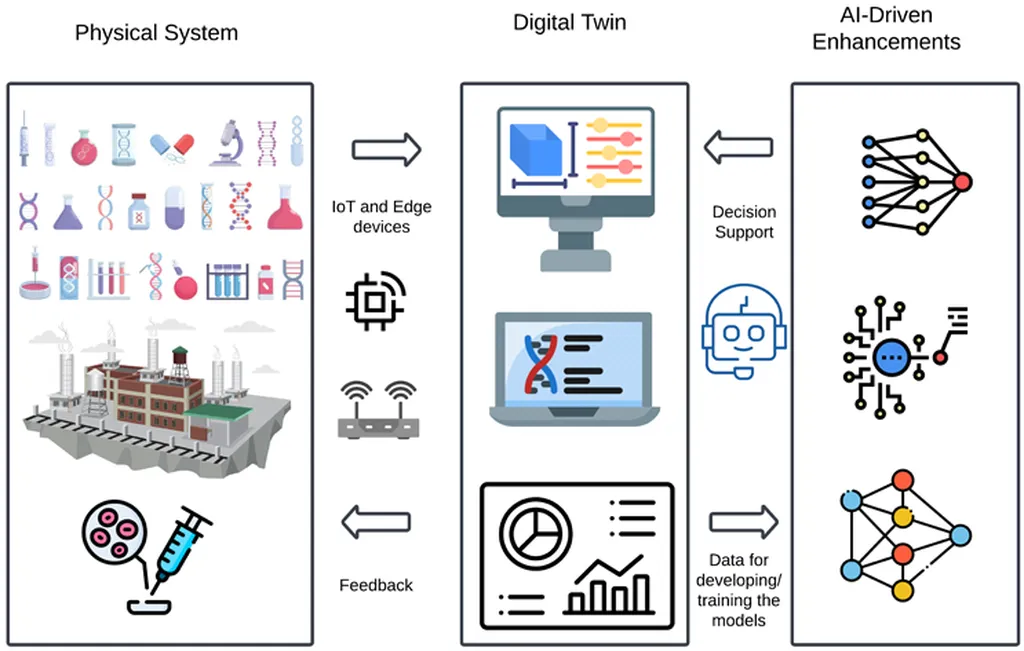

The framework consists of four core modules: Transplanting Status Detection, Multi-sensor Data Fusion, Digital Twin Visualization, and Operational Optimization Feedback. At the heart of this system is a lightweight improved YAN-YOLO11 algorithm, which is capable of detecting and assessing normal, exposed-root, and buried seedlings with remarkable precision. By fusing GNSS positioning data with visual detection results, the system can estimate in-row spacing and assess the status of missed and double planting.

One of the most compelling aspects of this research is its potential to significantly enhance the digitalization, automation, and refined management of tobacco transplanting operations. “This study effectively enhances the digitalization, automation, and refined management of tobacco transplanting operations, providing a theoretical foundation and practical solution for the intelligent transformation of transplanting machinery and precision crop management,” said Qiuyang Zhao, the lead author of the study.

The system’s ability to visualize operational status in real-time and generate replanting path suggestions offers invaluable guidance for operation management. This not only improves inspection efficiency but also supports replanting decisions and transplanting machine optimization. Field experiments have demonstrated that the improved YAN-YOLO11 algorithm achieves a real-time performance of 30 FPS, with an overall recognition accuracy of 90.74%, meeting practical application requirements.

The commercial implications of this research are substantial. By reducing the reliance on manual inspection, the framework can lower labor costs and increase operational efficiency, ultimately leading to higher crop yields and improved tobacco leaf quality. This innovation has the potential to reshape the agriculture sector, particularly in regions where tobacco production is a significant economic driver.

Looking ahead, this research paves the way for future developments in the field of precision agriculture. The integration of deep learning and digital twin technology opens up new possibilities for automating and optimizing various aspects of crop management. As the agriculture sector continues to embrace digital transformation, such advancements will play a crucial role in enhancing productivity and sustainability.

In conclusion, the digital twin-driven deep learning framework for online quality inspection in tobacco transplanting represents a significant leap forward in agricultural technology. With its potential to improve efficiency, accuracy, and decision-making, this innovation is poised to make a lasting impact on the industry. As researchers continue to explore and refine these technologies, the future of precision agriculture looks increasingly promising.