In the quest for sustainable solutions, researchers have turned an often-overlooked byproduct of gelatin capsule production into a promising ingredient for functional foods. A recent study published in the journal *Future Foods* (translated as “Future Foods”) explores the potential of repurposing gelatin capsule waste (GCW) into hydrogels, enhancing their properties with kappa-carrageenan. This innovation could pave the way for more sustainable and functional food applications, particularly in the soft confectionery sector.

The study, led by Sasina Sanprasert from the Department of Fishery Products at Kasetsart University in Bangkok, Thailand, investigated the techno-functional gelling mechanisms and rheological properties of gelatin waste gel modified with varying levels of kappa-carrageenan. The findings reveal that incorporating carrageenan significantly improves the gel’s texture and strength, making it a viable candidate for future food applications.

“By substituting gelatin capsule waste with carrageenan, we observed notable enhancements in the gel’s texture and strength,” Sanprasert explained. “This modification not only improves the gel’s functional properties but also offers a sustainable solution to the waste generated during gelatin capsule production.”

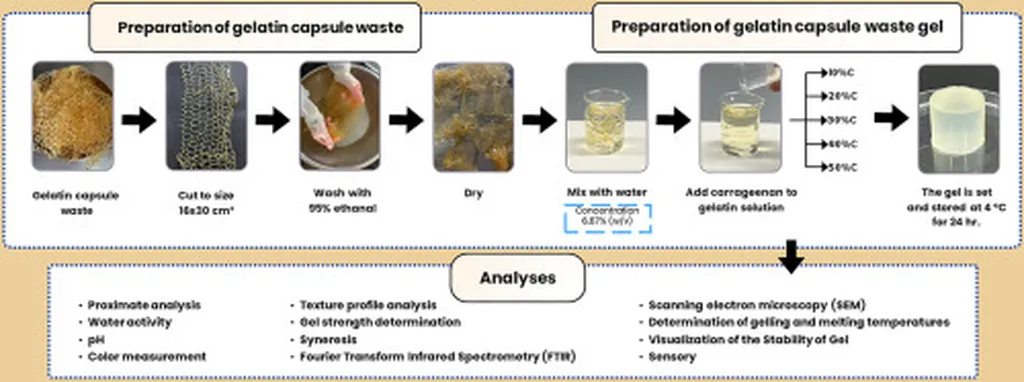

The research involved substituting GCW with carrageenan at different levels (0%, 10%, 20%, 30%, 40%, or 50% w/w). The results showed that the addition of carrageenan increased the gel’s texture profile analysis and gel strength. Synchrotron Radiation-based Fourier-Transform Infrared Spectroscopy (SR-FTIR) identified intermolecular and intramolecular interactions between the gelatin and carrageenan, contributing to the enhanced properties.

Rheological measurements further revealed that the incorporation of carrageenan influenced the elastic modulus (G’) and loss modulus (G’’) of the substituted GCW gel. The temperature sweep tests coincided with higher gelling and melting temperatures, indicating improved stability. Additionally, the substituted GCW gels exhibited higher turbidity and a finer gel network with smaller voids compared to the unmodified GCW gel.

However, the study also noted a decrease in the overall likeness score for the gels substituted with carrageenan, especially at higher levels. This suggests that while the modified gels offer improved functional properties, there is a trade-off in terms of sensory acceptance.

The commercial implications of this research are significant. The gelatin industry generates substantial waste, and repurposing this waste into functional hydrogels could offer a sustainable and cost-effective solution. The enhanced properties of the modified gels make them suitable for various food applications, particularly in the soft confectionery sector, where texture and stability are crucial.

As the food industry continues to seek sustainable and functional ingredients, this research highlights the potential of gelatin capsule waste as a valuable resource. By leveraging innovative technologies and sustainable practices, the food industry can reduce waste and develop new, functional products that meet consumer demands.

“This research opens up new possibilities for the gelatin industry,” Sanprasert added. “By repurposing waste into functional hydrogels, we can create value-added products that are both sustainable and beneficial for the food industry.”

The study published in *Future Foods* (translated as “Future Foods”) not only advances our understanding of gelatin waste repurposing but also sets the stage for future developments in the field of functional foods. As the industry continues to evolve, the integration of sustainable practices and innovative technologies will be key to meeting the demands of a growing and increasingly conscious consumer base.