In the quest to enhance meat preservation techniques, a groundbreaking study led by Xiaomei Dai from the Department of Food Science and Technology at Jiangsu Food & Pharmaceutical Science College in China has unveiled a novel method that could revolutionize the industry. The research, published in *Results in Engineering* (translated as *Research Results in Engineering*), focuses on a sustainable and effective approach to preserving beef using anthocyanin-enriched films derived from camphor fruit waste.

Meat preservation has long been plagued by challenges such as lipid oxidation, moisture loss, and texture degradation, which significantly impact the quality and shelf life of products. Traditional methods like freeze-drying (FD), vacuum drying (VD), and hot-air drying (HAD) often fall short in addressing these issues comprehensively. However, Dai’s innovative film drying technique has shown promising results that could set new standards in the field.

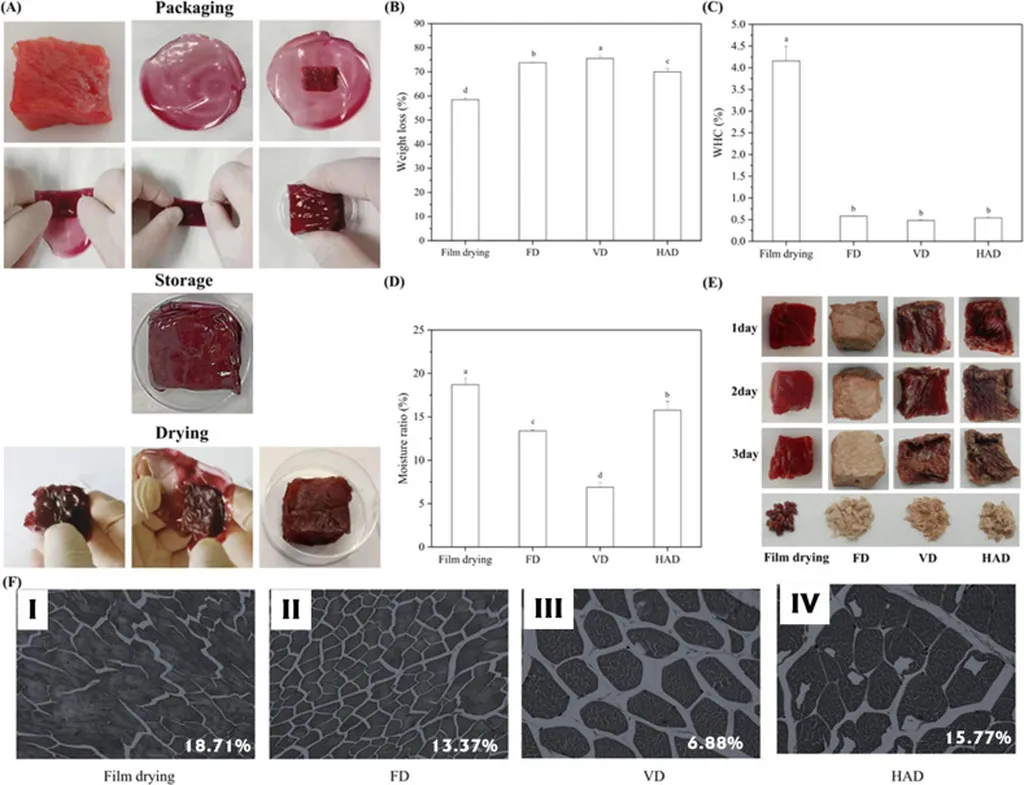

The study compared the effectiveness of film drying against conventional methods, revealing that film-dried beef exhibited significantly lower weight loss and higher water-holding capacity. “The film-dried beef retained up to 58.44% of its weight and had a water-holding capacity of 4.16%, which is substantially better than the other methods,” Dai explained. This superior moisture retention is crucial for maintaining the texture and overall quality of the meat.

One of the most striking findings was the reduction in lipid oxidation. The thiobarbituric acid reactive substances (TBARS) values for film-dried beef were remarkably lower at 0.30 mg MDA/kg compared to 0.59 mg MDA/kg for hot-air dried beef. This indicates that film drying effectively minimizes oxidative degradation, a critical factor in extending the shelf life of meat products.

Rehydration properties were also superior in film-dried samples, with a moisture ratio of 18.71% after 60 minutes, compared to 13.37% for freeze-dried beef and significantly lower values for vacuum and hot-air dried samples. Texture analysis further confirmed the advantages of film drying, with beef retaining better hardness, chewiness, and cohesiveness than samples preserved using conventional methods.

Electronic nose analysis added another layer of insight, showing that film drying reduced volatile sulfide and aromatic compounds, enhancing the overall sensory quality of the meat. Sensory evaluations corroborated these findings, with film-dried beef receiving higher acceptability scores in color, texture, and overall quality.

The implications of this research are far-reaching. For the meat industry, this novel method offers a sustainable and effective solution to enhance product quality and extend shelf life. The use of camphor fruit waste to create anthocyanin-enriched films not only valorizes food waste but also provides an eco-friendly alternative to traditional preservatives.

As the world grapples with the challenges of food waste and sustainability, Dai’s research offers a beacon of hope. “This method not only improves the quality of meat products but also contributes to a circular economy by utilizing agricultural waste,” Dai noted. The potential commercial impacts are substantial, with opportunities for energy savings and reduced environmental footprint in meat processing facilities.

Looking ahead, this research could pave the way for further innovations in food preservation technologies. The integration of sustainable materials and advanced drying techniques holds promise for a future where food waste is minimized, and product quality is maximized. As the food industry continues to evolve, Dai’s work serves as a testament to the power of innovation in addressing global challenges.

In the ever-evolving landscape of food science and technology, this study stands out as a significant milestone. With its focus on sustainability, quality, and efficiency, it sets a new benchmark for meat preservation techniques. As the findings are further explored and implemented, the future of food preservation looks brighter and more promising than ever before.