In the heart of Guizhou, China, a team of researchers has unlocked a new method to optimize the extraction process of Eucommia ulmoides gum, a valuable natural polymer with applications in food, pharmaceuticals, and cosmetics. This breakthrough, published in the journal ‘Hecheng xiangjiao gongye’, could significantly boost the agricultural sector’s output and efficiency.

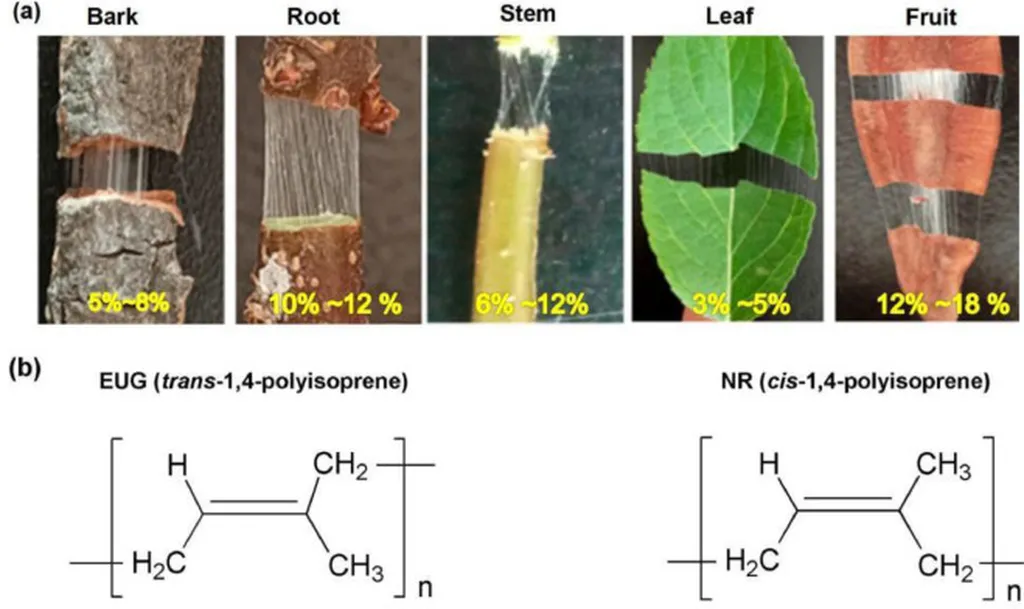

Eucommia ulmoides gum, derived from the bark of the Eucommia ulmoides tree, has long been prized for its unique properties. However, extracting it efficiently has been a challenge. Enter QU Peng-kun and ZHAO De-gang, lead authors of the study affiliated with the Guizhou Academy of Agricultural Sciences and Guizhou University. Their research has paved the way for a more streamlined extraction process using hydrogen peroxide pretreatment and advanced optimization techniques.

The team began by conducting single-factor tests to understand the impact of various parameters on the extraction rate. They varied the amount of hydrogen peroxide, pretreatment temperature, pretreatment time, and solid-liquid ratio. This initial phase laid the groundwork for more sophisticated experiments.

“Single-factor tests are crucial as they help us understand the individual effects of each parameter,” explained QU Peng-kun. “This foundational knowledge is essential before moving on to more complex optimization techniques.”

Next, the researchers employed orthogonal tests and Box-Behnken response surface optimization methods to construct a model that could predict the optimal extraction conditions. This approach allowed them to fine-tune the process with remarkable precision.

The results were impressive. The optimal conditions identified were a hydrogen peroxide mass fraction of 6%, a pretreatment temperature of 95°C, a pretreatment time of 2.0 hours, and a solid-liquid ratio of 1 g/20 mL. For the reflux extraction stage, the optimal conditions were a reflux time of 5 hours, a single extraction, and the same solid-liquid ratio.

Under these optimized conditions, the actual extraction rate of Eucommia ulmoides gum reached 10.48%, a significant improvement over the unoptimized process. This enhancement could have profound implications for the agricultural sector, particularly for farmers and producers of Eucommia ulmoides gum.

“The optimized process not only increases the extraction rate but also reduces waste and improves efficiency,” said ZHAO De-gang. “This is a win-win situation for both the environment and the industry.”

The commercial impacts of this research are substantial. By optimizing the extraction process, producers can increase their yield and reduce costs, making Eucommia ulmoides gum more accessible and affordable. This could open up new markets and applications for the versatile natural polymer.

Looking ahead, this research could shape future developments in the field of natural polymer extraction. The methods used in this study could be applied to other natural polymers, potentially revolutionizing the way we extract and utilize these valuable resources.

As the world increasingly turns to natural and sustainable solutions, the work of QU Peng-kun, ZHAO De-gang, and their team offers a glimpse into a future where agriculture and technology converge to create more efficient, sustainable, and profitable practices. Their research, published in ‘Hecheng xiangjiao gongye’, is a testament to the power of innovation and the potential it holds for the agricultural sector.