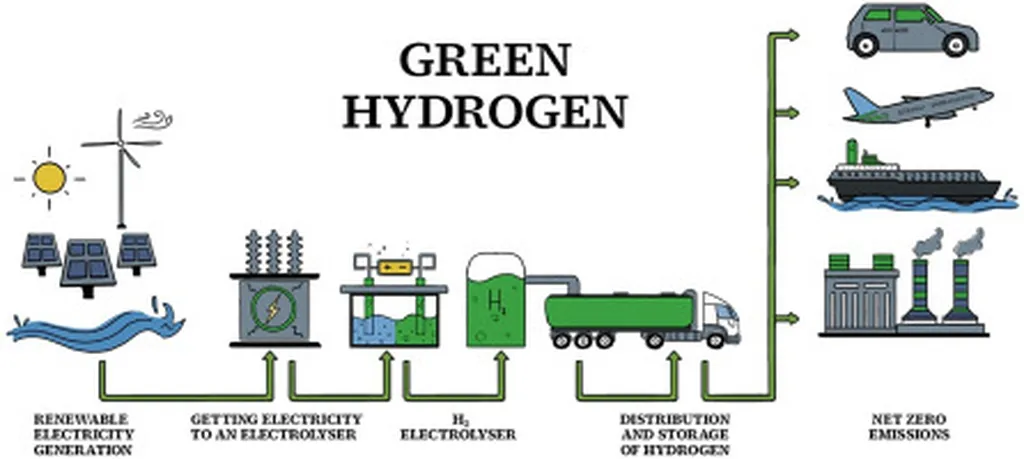

In a significant stride towards sustainable energy, researchers have developed a novel co-electrolysis system that could revolutionize green hydrogen production, offering a promising avenue for the agriculture sector to valorize biomass. The study, published in *eScience*, demonstrates a method that not only enhances the efficiency of hydrogen generation but also reduces costs, making it a viable alternative to conventional, fossil-fuel-based hydrogen production.

The research, led by Xin Zhao from the College of Resources and Environmental Sciences at China Agricultural University and the School of Chemistry, Chemical Engineering and Biotechnology at Nanyang Technological University, focuses on the selective oxidation of glucose derived from biomass. Instead of oxidizing water to produce oxygen—a process that requires expensive membranes to separate hydrogen and oxygen—the system selectively oxidizes glucose to formate. This innovation circumvents the need for costly membranes and significantly lowers the overall electrolysis potential by approximately 400 millivolts.

“By regulating the adsorption mode and moderating the oxidation state of cobalt with copper doping, we achieved high selectivity in the oxidation process,” Zhao explained. “This cascade carbon–carbon bond oxidation allows us to produce formate with high yields of up to 80%, making the process both efficient and economically viable.”

The implications for the agriculture sector are substantial. Biomass, a abundant byproduct of agricultural activities, can be valorized through this process, turning what is often considered waste into a valuable resource. The revenue generated from the formate co-product can lower the levelized cost of hydrogen production by $4.63 per kilogram, making green hydrogen competitive with grey hydrogen generated from fossil fuels.

“This research opens up new possibilities for the agricultural industry to contribute to the renewable energy sector,” said a spokesperson for the research team. “By converting biomass into high-value products like formate and green hydrogen, farmers and agribusinesses can diversify their revenue streams and reduce their environmental footprint.”

The study also highlights the potential for future developments in the field of solar reforming and green hydrogen production. As the world seeks to transition to renewable energy sources, innovations like this co-electrolysis system could play a crucial role in making green hydrogen a mainstream energy solution.

“The key to unlocking the full potential of renewable energy lies in developing efficient and cost-effective technologies,” Zhao noted. “Our research is a step in that direction, but there is still much to explore. We hope our findings will inspire further innovation in the field.”

As the global push for sustainability gains momentum, this research offers a glimpse into a future where agriculture and renewable energy intersect, creating a symbiotic relationship that benefits both industries and the environment. With continued advancements, the vision of a sustainable energy future powered by green hydrogen and biomass valorization could become a reality.