In the quest for sustainable and efficient food production, Controlled Environment Agriculture (CEA) has emerged as a promising alternative to traditional farming. However, the energy-intensive nature of these systems, particularly due to temperature regulation, poses significant challenges. A recent review published in ‘Agronomy’ sheds light on the impact of high temperature stress on crops in CEA and explores the potential of biostimulants to mitigate these effects, offering a glimpse into the future of sustainable agriculture.

CEA, which includes greenhouses and vertical farms, can produce yields 10 to 100 times higher than open-field agriculture while using a fraction of the water. However, maintaining optimal temperatures in these systems can be energy-intensive, leading to higher operational costs and environmental footprints. “Energy is the second largest overhead cost in CEA,” notes lead author Anna Gardiner-Piggott from Lancaster Environment Centre, Lancaster University. “Carbon footprints in these systems can be 5.6–16.7 times greater than that of open-field agriculture for indoor vertical farms and 2.3–3.3 times greater for greenhouses.”

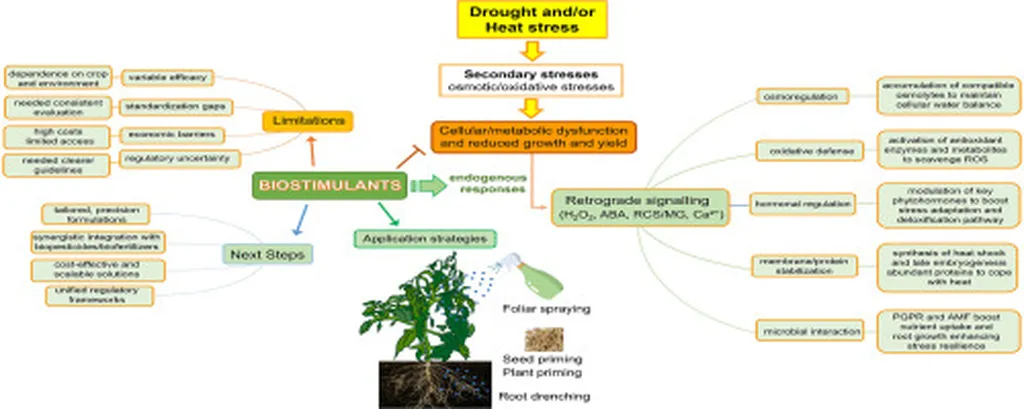

High temperatures can wreak havoc on crops, affecting their morphology, cellular structure, metabolism, and molecular processes, ultimately reducing both quality and quantity of produce. This is where biostimulants come into play. These additives can enhance plant growth and ameliorate stress, offering a potential solution to the challenges posed by high temperature stress in CEA.

The review explores various categories of biostimulants, including seaweed extracts, chitin/chitosan, protein hydrolysates and amino acids, inorganic compounds, beneficial microorganisms, and humic substances. Each of these has shown promise in mitigating heat stress in crops, but they also come with their own set of limitations and knowledge gaps.

For instance, seaweed extracts have been shown to enhance heat stress tolerance in crops like lettuce and tomato, but the optimal application rates and frequencies are still not well understood. Similarly, while chitin/chitosan has demonstrated potential in improving plant defense mechanisms, its application in CEA is still in the early stages.

The commercial implications of this research are significant. By reducing the reliance on cooling systems through the use of biostimulants, CEA operations could see a substantial reduction in energy costs. This could make CEA more economically viable and environmentally sustainable, paving the way for wider adoption of these systems.

Moreover, the use of biostimulants could also lead to improvements in crop quality and yield, further enhancing the commercial potential of CEA. As Gardiner-Piggott puts it, “Biostimulants offer a promising avenue for mitigating heat stress in CEA, but more research is needed to fully understand their potential and limitations.”

This research could shape the future of CEA in several ways. It highlights the need for further investigation into the use of biostimulants and their potential to enhance crop resilience in CEA. It also underscores the importance of developing more energy-efficient temperature regulation strategies to make CEA more sustainable and economically viable.

In the end, the review serves as a call to action for the agriculture sector to explore innovative solutions to the challenges posed by high temperature stress in CEA. By doing so, we can pave the way for a more sustainable and efficient future for food production.