In the quest to transform agricultural waste into valuable resources, researchers have made significant strides in optimizing the extraction of pectin from pomelo peels. A recent study published in the *Journal of Agriculture and Food Research* delves into the impact of different extraction methods on the physicochemical and structural characteristics of pomelo peel pectin, offering promising insights for the agriculture and food industries.

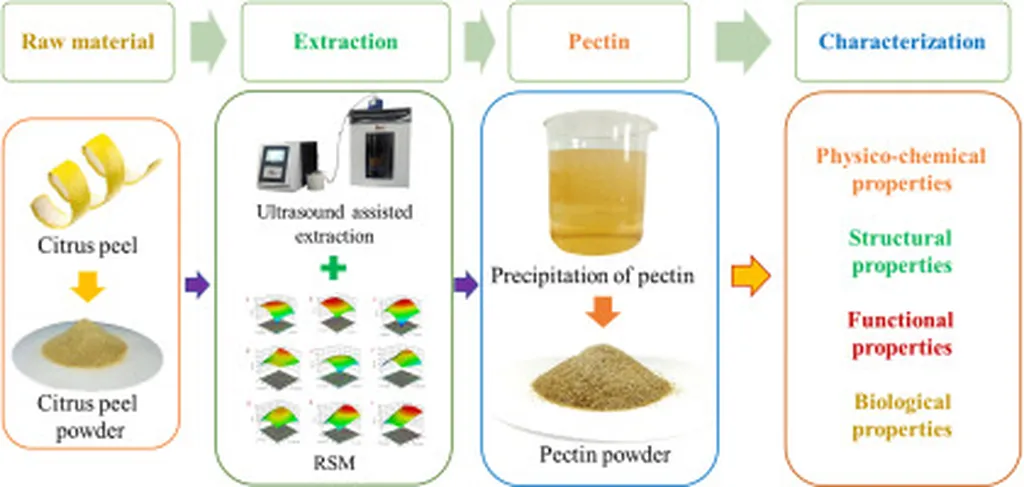

Pectin, a polysaccharide found in the cell walls of plants, is widely used as a gelling agent, stabilizer, and thickener in food products. The study, led by Danni Lin from the Department of Food Science and Technology at Jinan University in Guangzhou, China, explored four extraction methods: acid extraction (HAE), acid-ultrasound extraction (US–HAE), alkaline extraction (BE), and alkaline-ultrasound extraction (US–BE). The findings reveal that the choice of extraction method significantly influences the yield, molecular weight, purity, and structural properties of the extracted pectin.

Acid extraction methods (HAE and US–HAE) yielded higher quantities of pectin with larger molecular weights compared to alkaline methods (BE and US–BE). Notably, the use of ultrasound in acid extraction increased the yield by 1.79% and the purity by 7.62% compared to traditional acid extraction. “Ultrasound-assisted extraction not only enhances the yield and purity of pectin but also reduces its degree of esterification and molecular weight without significantly affecting its viscosity or gel strength,” explained Lin. This suggests that ultrasound technology could be a game-changer in the efficient and cost-effective production of high-quality pectin.

The structural analysis showed that acid-extracted pectins exhibited a higher degree of esterification, predominantly homogalacturonan-rich structures, and a more linear conformation. In contrast, alkali-extracted pectins displayed lower degrees of esterification, smaller molecular weights, and more complex rhamnogalacturonan I side chains. The apparent viscosity, gel strength, and emulsifying properties of acid-extracted pectins were significantly higher than those of alkali-extracted pectins, indicating their superior functional properties for industrial applications.

The study also highlighted that ultrasound treatment promoted the accumulation of galacturonic acid (GalA) in the primary chain, enhancing linearity and increasing the degree of structural fragmentation. This structural modification could lead to the development of pectin with tailored functionalities for specific applications in the food and pharmaceutical industries.

The commercial implications of this research are substantial. By optimizing the extraction process, agricultural waste such as pomelo peels can be converted into high-value products, reducing waste and creating new revenue streams for farmers and processors. The enhanced functional properties of acid-extracted pectins, particularly those obtained through ultrasound-assisted methods, open up new possibilities for their use in food products, pharmaceuticals, and other industrial applications.

As the global demand for natural and sustainable ingredients continues to grow, the findings of this study provide a theoretical basis for the high-value utilization of pomelo peel pectin. The research also underscores the importance of designing function-oriented extraction processes to meet the diverse needs of the market. With further advancements in extraction technologies and a deeper understanding of pectin’s structural properties, the agriculture sector can look forward to a future where waste is minimized, and value is maximized.

In the words of Lin, “This study not only provides a deeper understanding of the extraction process but also paves the way for the development of innovative pectin-based products with enhanced functionalities.” As the agriculture industry continues to evolve, such research will be crucial in driving sustainable practices and fostering economic growth.