In the rugged, unforgiving landscapes where few organisms dare to tread, a tenacious black fungus, Knufia chersonesos, has been quietly evolving an arsenal of enzymes that could revolutionize industrial processes, particularly in agriculture. This extremophile, thriving on rocks and other harsh environments, has captured the attention of researchers who see its potential in breaking down synthetic materials, offering a glimpse into sustainable solutions for biological plastics recycling.

The recent study, published in *Frontiers in Bioengineering and Biotechnology*, delves into the enzymatic secrets of K. chersonesos. Led by Sophia Mihalyi at the Institute of Environmental Biotechnology, Department of Agricultural Sciences, IFA Tulln, BOKU University, the research identifies two key enzymes: a cutinase (Kc_Cut) and a lipase (Kc_Lip). These enzymes, produced by the fungus when fed poly (butylene-adipate-co-terephthalate) (PBAT), a type of biodegradable plastic, exhibit remarkable activity under extreme conditions.

“These enzymes are not just surviving; they are thriving in conditions that would be detrimental to most biological systems,” Mihalyi explains. The enzymes were recombinantly expressed in Komagataella phaffii and Trichoderma reesei for further characterization. The purified enzymes showed specific activities of 83 ± 1 and 0.23 ± 0.02 U mg⁻¹ on para-nitrophenylbutyrate (p-NPB), respectively, indicating their potential for industrial applications.

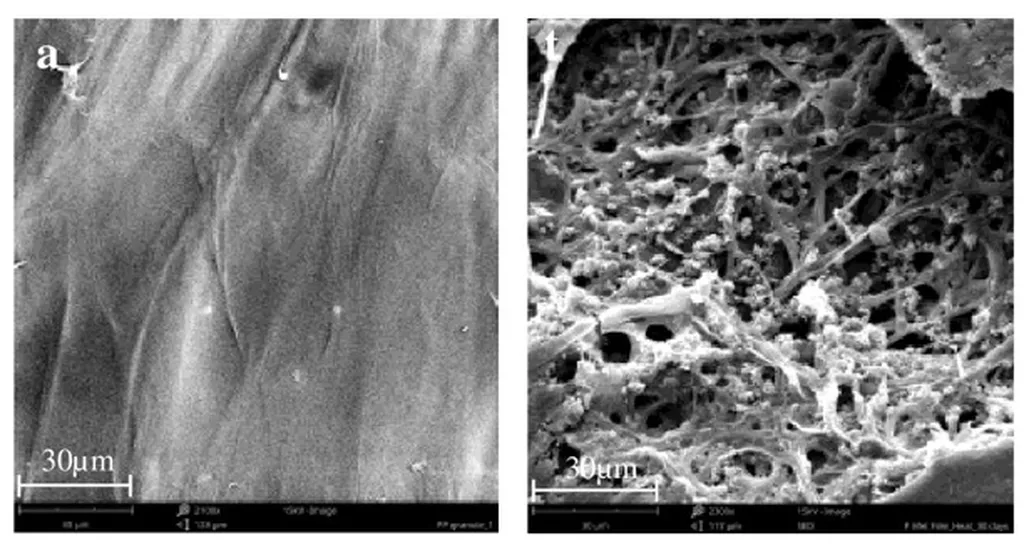

The optimum conditions for Kc_Cut were found to be 50°C, pH 8, and 100 mM potassium phosphate buffer. When incubated with PBAT powder for 72 hours, Kc_Cut released 17 ± 1 µM of terephthalic acid (Ta), while Kc_Lip liberated the trimer BTaB. This cooperative action suggests a synergistic relationship between the two enzymes, providing valuable insights into the metabolic potential and adaptability of K. chersonesos.

The implications for the agriculture sector are profound. As the world grapples with the environmental impact of synthetic materials, the ability to break down biodegradable plastics efficiently and sustainably is a game-changer. “This research opens up new avenues for developing enzymes that can operate in extreme environments, which is crucial for agricultural applications where conditions can be highly variable,” Mihalyi notes.

The study not only highlights the potential of K. chersonesos but also underscores the importance of exploring extremophiles for industrial biotechnology. As we move towards a more sustainable future, the enzymes from this resilient fungus could play a pivotal role in breaking down synthetic materials, reducing waste, and mitigating environmental impact.

The research, led by Sophia Mihalyi at the Institute of Environmental Biotechnology, Department of Agricultural Sciences, IFA Tulln, BOKU University, published in *Frontiers in Bioengineering and Biotechnology*, offers a promising glimpse into the future of biological plastics recycling and its potential to transform the agriculture sector.