In the quest for sustainable agriculture and industrial practices, researchers are increasingly turning to underutilized agricultural waste streams for innovative solutions. A recent study published in *Industrial Crops and Products* explores the potential of sugar beet pulp (SBP), a byproduct of sugar production, as a valuable feedstock for biorefineries. This research, led by Kawinharsun Dhodduraj from the Faculty of Engineering and Applied Sciences at Cranfield University in the United Kingdom, sheds light on how SBP can be transformed into a range of value-added chemicals, offering significant economic and environmental benefits for the agriculture sector.

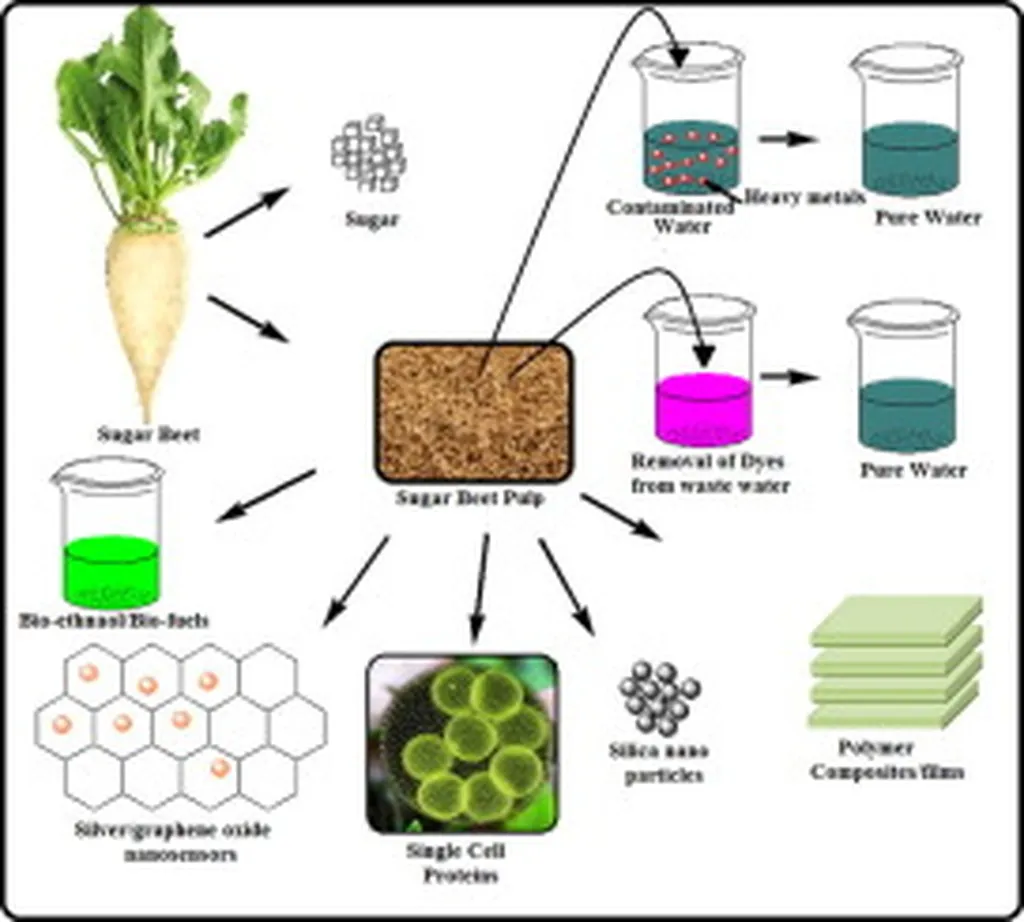

Sugar beet is a major crop in the European Union and the United States, primarily grown for sugar production. After extracting sucrose, the remaining fibrous fraction, known as sugar beet pulp, is often underutilized. However, this pulp is rich in structural carbohydrates such as cellulose, hemicellulose, and pectin, which contain fermentable sugars like glucose, arabinose, and galacturonic acid. These sugars constitute about 85% of the total carbohydrates in SBP, making it a promising renewable resource for biorefineries.

The study highlights current advances in SBP valorization, beginning with an overview of sugar beet processing and waste generation. It critically assesses various pretreatment strategies that enhance carbohydrate accessibility, a crucial step in converting SBP into valuable products. “Pretreatment is a key factor in unlocking the full potential of sugar beet pulp,” explains Dhodduraj. “By improving the accessibility of carbohydrates, we can significantly enhance the efficiency of subsequent bioconversion processes.”

One of the most exciting aspects of this research is its focus on emerging routes for the bioconversion of arabinose and galacturonic acid, which together represent more than half of SBP’s fermentable fraction. These sugars are often underutilized in industrial biotechnology, but the study examines microbial pathways, metabolic engineering interventions, and fermentation approaches that enable the production of value-added compounds such as arabitol, 2,3-butanediol, ascorbic acid, mucic acid, and prebiotics.

The commercial implications of this research are substantial. By leveraging SBP as a substrate for biorefineries, the agriculture sector can reduce waste and generate additional revenue streams. “This approach supports circular bioeconomy principles by simultaneously reducing agricultural waste and enabling the sustainable production of value-added chemicals,” notes Dhodduraj. “It’s a win-win situation for both the environment and the industry.”

The study also addresses current challenges and identifies research gaps that need to be addressed to unlock the full potential of SBP within integrated biorefinery systems. As the agriculture sector continues to seek sustainable and economically viable solutions, research like this paves the way for innovative applications of agricultural waste. The findings could shape future developments in the field, encouraging further investment and research into the valorization of sugar beet pulp and other underutilized agricultural byproducts.

In an era where sustainability and efficiency are paramount, this research offers a glimpse into a future where agricultural waste is not just discarded but transformed into valuable resources. As Dhodduraj and his team continue to explore the potential of sugar beet pulp, the agriculture sector stands to benefit from new opportunities and a more sustainable approach to resource utilization.