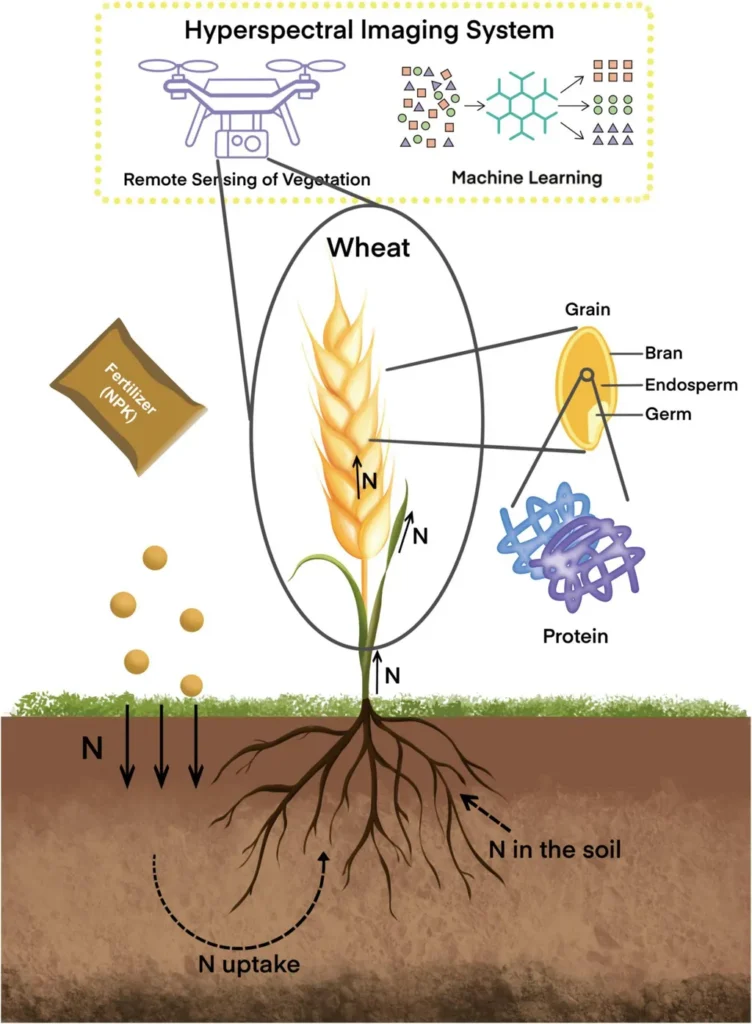

In a groundbreaking development for the agriculture sector, researchers have combined deep learning and hyperspectral imaging to create a rapid, non-destructive method for assessing crude protein content in individual wheat kernels. This innovation, published in the *Journal of Agriculture and Food Research*, promises to revolutionize quality control and processing in the grain industry.

Traditionally, determining wheat crude protein content—a critical parameter for food processing—has relied on destructive chemical methods like Kjeldahl or Dumas assays. While near-infrared (NIR) spectroscopy offers a non-destructive alternative, its localized measurement approach has limited its scalability. The new study, led by Jae Gyeong Jung of Chungnam National University in South Korea, presents a cutting-edge solution that integrates deep learning-based segmentation with hyperspectral imaging and Partial Least Squares Regression (PLSR).

The research team compared Visible and Near-Infrared (VNIR) and Short-Wave Infrared (SWIR) spectral regions for protein prediction. Using the YOLOv11 segmentation model, they achieved exceptional accuracy (F1 score >0.99) across both spectral ranges, enabling automated extraction of individual kernel spectra. “The YOLOv11 model not only provided high accuracy but also significantly improved inference speed, making it approximately 2.57 times faster than YOLOv8,” Jung explained. This speed is crucial for high-throughput analysis in commercial settings.

Three preprocessing methods—Standard Normal Variate (SNV), Multiplicative Scatter Correction (MSC), and Savitzky-Golay—were systematically evaluated. The SWIR-based PLSR models consistently outperformed their VNIR counterparts, with the best SWIR model achieving a Test R2 of 0.8725, RMSE of 0.7479, and Q2 of 0.8738 using MSC preprocessing. Notably, Savitzky-Golay preprocessing offered the optimal model simplicity, reducing PLS components from 10 to 3 while maintaining robust generalization.

The implications for the agriculture sector are profound. This integrated platform could streamline quality assessment in grain processing facilities, quality control laboratories, and automated raw material sorting systems. “The combination of high-speed deep learning segmentation with SWIR hyperspectral imaging establishes a practical framework for non-destructive quality assessment,” Jung said. This technology could enhance efficiency, reduce waste, and improve the overall quality of wheat products, benefiting both producers and consumers.

As the agriculture industry continues to embrace technological advancements, this research paves the way for future developments in non-destructive phenotyping and quality control. The integration of deep learning and hyperspectral imaging holds promise for a wide range of applications, from crop monitoring to food safety, ultimately shaping the future of sustainable and efficient agriculture.