In a significant stride towards sustainable biomanufacturing, researchers have engineered the yeast Yarrowia lipolytica to produce high levels of squalene, a valuable compound with wide-ranging applications in nutraceuticals and health industries. The study, published in *Synthetic and Systems Biotechnology*, demonstrates a novel approach combining metabolic engineering and adaptive laboratory evolution to enhance squalene production, offering promising avenues for the agriculture sector.

Squalene, a natural compound found in small quantities in various plants and animals, is highly sought after for its antioxidant properties and potential health benefits. Traditional extraction methods are often costly and environmentally taxing. Microbial production provides a sustainable alternative, and this research pushes the boundaries of what’s possible.

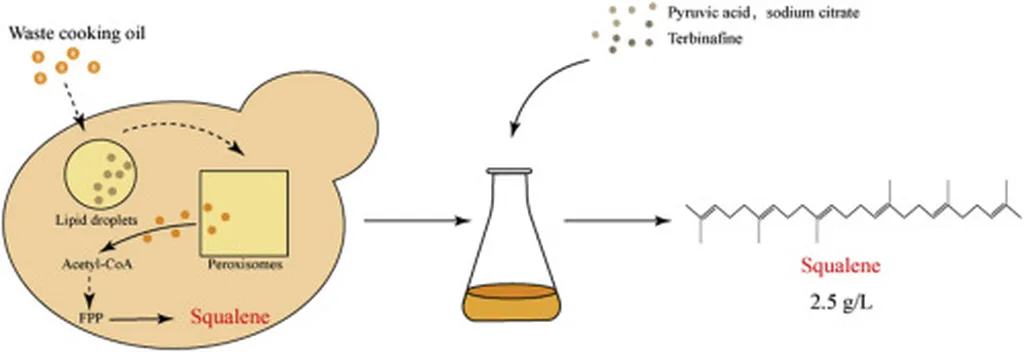

The team, led by Qiao-Qin Zhao from the College of Bioscience and Biotechnology at Hunan Agricultural University, systematically optimized squalene production in Yarrowia lipolytica. They first induced lipid droplet expansion and proliferation by overexpressing DGA1 and LRO1, enabling efficient accumulation of intracellular squalene. “By enhancing the lipid droplet capacity, we created a more hospitable environment for squalene synthesis,” Zhao explained.

The researchers then employed an enzyme fusion strategy to improve the catalytic efficiency between ERG20 and SQS, key enzymes in the squalene synthesis pathway. This strategy increased the flux towards squalene production. Additionally, they enhanced the expression of ScHMG1, a rate-limiting enzyme in the mevalonate (MVA) pathway, to optimize precursor supply.

The final step involved adaptive laboratory evolution induced by hydrogen peroxide, which generated the evolved strain SY8–H3. This strain produced an impressive 801.34 mg/L of squalene in shake-flask fermentation and 4.53 g/L via fed-batch fermentation in a 2.4 L bioreactor. “Adaptive evolution under oxidative stress was a game-changer,” Zhao noted. “It allowed us to select for strains with enhanced robustness and productivity.”

The implications for the agriculture sector are substantial. Squalene’s applications in cosmetics, pharmaceuticals, and functional foods create a growing market demand. Microbial production offers a scalable, cost-effective solution that can be integrated into existing biomanufacturing infrastructures. This research not only advances the field of metabolic engineering but also sets a precedent for synthesizing other high-value compounds in engineered microbes.

As the world shifts towards sustainable and eco-friendly production methods, innovations like this are crucial. The study’s success in enhancing squalene production through metabolic engineering and adaptive evolution opens new possibilities for the agricultural biotechnology industry. It paves the way for future developments in microbial production systems, potentially revolutionizing how we manufacture valuable bio-based products.

The research, led by Qiao-Qin Zhao and published in *Synthetic and Systems Biotechnology*, marks a significant milestone in the quest for sustainable biomanufacturing. As the agriculture sector continues to evolve, such advancements will play a pivotal role in meeting the growing demand for high-value, eco-friendly products.